Procurement in engineering refers to the process of acquiring goods, services, and materials needed to complete engineering projects. This includes everything from raw materials, machinery, and components to specialized services like consulting or contracting. Effective procurement ensures that projects have the necessary resources delivered on time, at the right cost, and with the required quality.

In this blog, we’ll delve deeper into what procurement in engineering is, why it’s essential, and how it directly impacts project success.

What is Procurement in Engineering?

Procurement in engineering refers to the entire process of sourcing, acquiring, and managing materials, goods, services, and equipment required for engineering projects. This process can involve anything from raw materials for construction and manufacturing to consulting services for specialized engineering tasks. Engineering procurement can also involve contracting third-party services, such as labor or project management.

The procurement process in engineering typically includes the following steps:

- Needs Assessment: At the very start of an engineering project, the team must identify what resources are needed. This involves evaluating the scope of the project, the required materials, tools, and technologies, and understanding the regulatory requirements.

- Supplier Identification: Once the needs are clearly defined, the next step is identifying suppliers who can deliver the required goods or services. This may involve researching potential suppliers, issuing Requests for Proposals (RFPs), and selecting the best vendors based on factors like quality, price, and reliability.

- Negotiation and Contracting: After identifying suppliers, procurement teams enter into negotiations to establish terms of the agreement. This step is crucial for locking in competitive pricing, ensuring deadlines are met, and defining clear expectations for quality and performance.

- Order Fulfillment and Delivery: Once contracts are signed, the procurement team ensures that orders are fulfilled as per specifications. Effective delivery logistics are crucial to keeping the project on schedule and ensuring that materials arrive in time for installation or use.

- Quality Control and Inspection: In engineering, quality control is paramount. Procurement teams often work with engineers to inspect materials and services before they are accepted, ensuring they meet all standards and specifications.

- Inventory and Supply Chain Management: Effective inventory management ensures that there is no overstock or shortage of materials. Procurement departments must balance demand and supply, often relying on technology and forecasting tools to maintain efficiency.

Read More: What is Procurement in Construction?

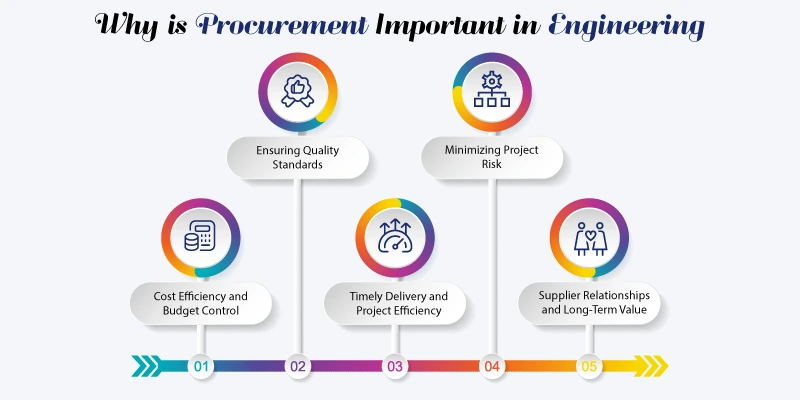

Why is Procurement Important in Engineering?

Procurement is a critical function in engineering for several reasons. It impacts cost, quality, delivery timelines, and overall project risk. Below are some of the key reasons why procurement is essential in engineering:

1. Cost Efficiency and Budget Control

Procurement plays a vital role in managing a project’s budget. The cost of materials, services, and equipment can make up a large portion of a project’s total expenses. A well-managed procurement process can reduce costs by securing competitive pricing, minimizing waste, and ensuring the most cost-effective solutions are chosen. Additionally, procurement teams negotiate payment terms and conditions that help manage cash flow throughout the project.

2. Ensuring Quality Standards

Quality control is an essential part of any engineering project. Procurement teams are responsible for ensuring that all materials, tools, and services meet the required standards for performance, durability, and compliance with industry regulations. By selecting suppliers who can consistently deliver high-quality goods, procurement minimizes the risk of defects, rework, or project delays.

3. Timely Delivery and Project Efficiency

Engineering projects are often complex and have tight schedules. Delays in procurement—whether it’s from late deliveries or unavailable materials—can result in significant project delays and increased costs. Effective procurement ensures that materials and services are delivered on time, which helps prevent bottlenecks and keeps projects on schedule.

4. Minimizing Project Risk

Procurement plays a central role in mitigating risks associated with engineering projects. By thoroughly vetting suppliers, evaluating their reliability, and ensuring compliance with safety and regulatory standards, procurement teams reduce the chances of encountering issues like defective materials, non-compliant practices, or late deliveries. This, in turn, reduces the risk of project failure.

5. Supplier Relationships and Long-Term Value

Developing strong relationships with suppliers is beneficial not just for individual projects but for the long-term success of an engineering firm. Suppliers can provide valuable insights, offer preferential pricing, or support rapid delivery in case of urgent needs. Maintaining strong supplier relationships also encourages cooperation, which can lead to better problem-solving and smoother project execution.

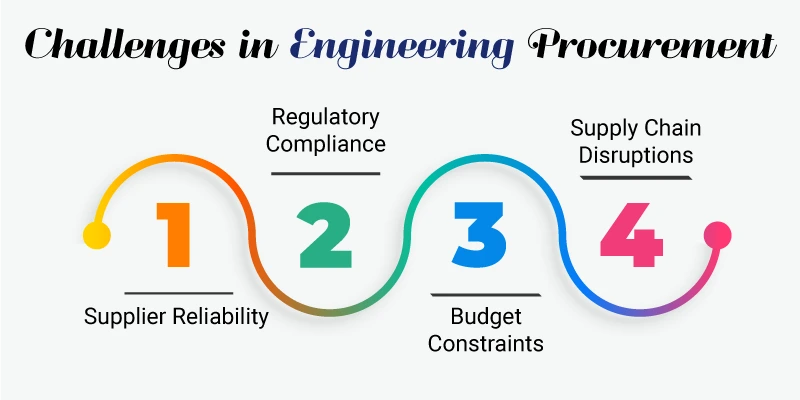

Challenges in Engineering Procurement

While procurement is crucial, it is not without its challenges. The procurement team must overcome several hurdles to ensure the project runs smoothly. These include:

1. Supplier Reliability

One of the biggest challenges in procurement is ensuring that suppliers can deliver on time and to the required quality. Engineering projects often rely on specialized materials and services, and a delay in procurement can halt the entire project. Ensuring a supplier has the capacity, reliability, and quality assurance processes in place is critical.

2. Regulatory Compliance

Engineering projects, especially in sectors like construction and manufacturing, must comply with local, national, and sometimes international regulations. Procurement teams must ensure that all goods and services sourced meet regulatory standards, including safety, environmental, and sustainability requirements. Failure to meet compliance standards can result in penalties, project delays, and safety risks.

3. Budget Constraints

The procurement process is highly sensitive to budget constraints. Price fluctuations in materials, shipping costs, and other external factors can make it challenging to keep procurement within budget. Procurement teams must continuously monitor the market, manage supplier negotiations, and evaluate alternatives to ensure the project stays within financial limits.

4. Supply Chain Disruptions

In today’s global market, supply chains are vulnerable to disruptions such as natural disasters, geopolitical tensions, and pandemics. These events can affect the availability of materials, transportation, and supplier performance. Procurement teams must plan for contingencies and develop strategies to manage such disruptions effectively.

Best Practices for Effective Procurement in Engineering

To overcome these challenges and ensure successful project delivery, procurement teams in engineering must implement best practices:

- Collaborate Across Departments: Effective communication between procurement and engineering teams is essential. Procurement needs to understand the technical requirements of the project to ensure the correct materials and services are acquired.

- Leverage Technology: Using procurement management software can streamline processes, improve inventory management, and enhance supplier tracking. Tools like Enterprise Resource Planning (ERP) systems can help track orders, costs, and compliance in real-time.

- Build Strong Supplier Networks: Building lasting, trust-based relationships with suppliers can lead to better terms, faster deliveries, and access to higher-quality materials. Reliable suppliers are often willing to work with you during crises or emergencies.

- Focus on Sustainability: As environmental concerns become more important, adopting sustainable procurement practices is essential. Engineering firms can select suppliers who provide eco-friendly products, which aligns with corporate responsibility goals and may even reduce costs in the long term.

- Conduct Thorough Risk Assessments: Regularly evaluating potential risks associated with suppliers, materials, and logistics will help identify vulnerabilities in the procurement process and allow teams to mitigate them proactively.

Also read: Procurement vs Logistics

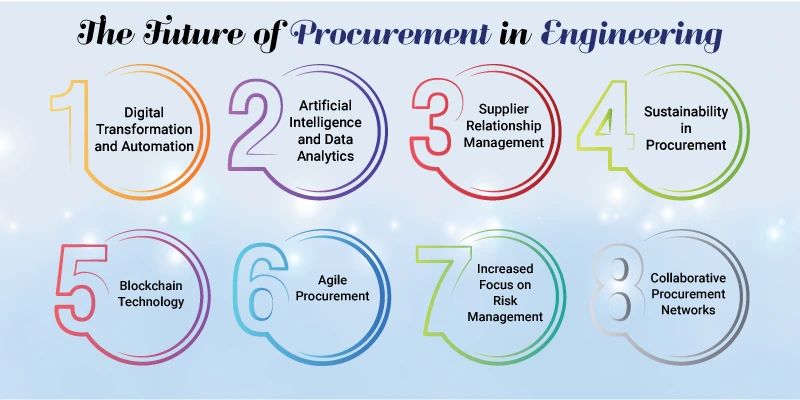

The Future of Procurement in Engineering

Procurement in engineering has been an essential function for decades, but as technology and the global market evolve, the role of procurement is undergoing a significant transformation. Here’s a look at the emerging trends and technologies that will define the future of procurement in the engineering sector.

1. Digital Transformation and Automation

As industries worldwide embrace digitalization, procurement in engineering is not far behind. Automation and digital procurement platforms are streamlining procurement processes, making them more efficient and transparent. Software systems like Enterprise Resource Planning (ERP) and Procurement Management Systems (PMS) are centralizing procurement activities, allowing teams to better manage orders, contracts, inventory, and supplier performance in real time.

Automation will reduce the burden of manual tasks, such as invoice processing and order tracking, freeing up procurement professionals to focus on higher-value tasks, such as strategic sourcing and supplier relationship management. Additionally, automation reduces human errors, minimizes delays, and enhances efficiency, ensuring projects stay on track.

2. Artificial Intelligence and Data Analytics

Artificial Intelligence (AI) and data analytics are transforming procurement in engineering by providing real-time insights, predictive analytics, and smarter decision-making tools. AI-powered tools can analyze vast amounts of data to predict demand, identify trends, and detect potential supply chain risks before they impact the project.

AI algorithms can also optimize sourcing decisions by analyzing supplier performance, prices, and delivery schedules. Over time, AI can learn from historical data, making procurement processes even more efficient and cost-effective. Additionally, data analytics will help procurement teams forecast material costs and manage inventory more effectively, reducing waste and costs.

3. Supplier Relationship Management

The future of procurement will focus more on building long-term, strategic relationships with suppliers rather than short-term transactional exchanges. Strong supplier relationships are essential for ensuring consistent product quality, timely deliveries, and mutually beneficial terms.

In the future, procurement teams will collaborate closely with suppliers to identify innovation opportunities, improve operational efficiency, and address challenges proactively. Strategic supplier partnerships can also foster sustainability initiatives, where both parties work together to reduce environmental impact and enhance supply chain resilience.

4. Sustainability in Procurement

Sustainability is no longer just a buzzword; it is a necessity in modern procurement practices, particularly in engineering projects. With growing concerns over climate change and resource depletion, engineering firms are increasingly expected to source materials and services that align with sustainable practices.

The future of procurement in engineering will see a greater emphasis on sustainable sourcing. This includes using renewable materials, selecting eco-friendly suppliers, and reducing carbon footprints throughout the supply chain. Additionally, green procurement practices will help organizations comply with regulatory pressures and meet corporate social responsibility (CSR) goals, providing long-term cost savings and enhancing brand reputation.

5. Blockchain Technology

Blockchain technology, which is already transforming various industries, is making its way into procurement. By providing a secure, transparent, and immutable record of all transactions, blockchain enhances the traceability of goods and services in the procurement process.

In engineering procurement, blockchain can ensure that materials are sourced ethically and that every step of the supply chain is visible and auditable. This is particularly important for compliance, fraud prevention, and ensuring the integrity of materials, especially in critical sectors like construction, manufacturing, and aerospace.

6. Agile Procurement

As engineering projects become more complex, organizations are moving toward agile procurement models. Traditional procurement methods can be slow, rigid, and focused on one-time transactions. However, agile procurement embraces flexibility, speed, and adaptability, enabling teams to adjust quickly to changes in project scope or unexpected challenges.

Agile procurement involves shorter procurement cycles, quick decision-making, and constant collaboration between procurement teams and project stakeholders. This will become increasingly important as projects require quick responses to market fluctuations, material shortages, or unexpected delays.

7. Increased Focus on Risk Management

Procurement in engineering will increasingly focus on risk management. Global disruptions, such as pandemics, geopolitical tensions, and supply chain bottlenecks, have highlighted the vulnerabilities in traditional procurement processes. As a result, procurement teams are placing more emphasis on managing and mitigating risks throughout the entire procurement cycle.

In the future, procurement will involve more comprehensive risk assessments, including supplier financial stability, geopolitical risks, and environmental factors. Companies will need to diversify their supplier base, invest in supply chain resilience, and develop contingency plans to manage potential disruptions effectively.

8. Collaborative Procurement Networks

The future of procurement will be more collaborative, with organizations leveraging shared procurement networks. This collaborative approach will enable businesses to pool resources, share information, and leverage economies of scale when sourcing materials or services.

In industries like construction and infrastructure, where multiple parties work on the same project, collaborative procurement networks will allow all stakeholders to align their procurement strategies, reduce waste, and improve efficiency. These networks will also promote transparency, ensuring that all parties involved are aware of the procurement process and timelines.

Optimizing Engineering Projects Through Procurement with SIXM

Procurement in engineering ensures efficiency, quality, and cost-effectiveness throughout the entire project lifecycle. As we’ve seen, strategic procurement can significantly impact project success, risk management, and innovation. At SIXM, we understand the importance of a streamlined procurement process and are committed to providing engineering solutions that help businesses thrive. For more information, explore our Mexico Sourcing & Procurement Engineering Services. Stay connected with us for more insights on optimizing your engineering projects and procurement strategies.