Production management focuses on efficiently coordinating people, processes, and resources to manufacture goods within budget and on schedule. It ensures smooth operations from raw materials to final output while maintaining quality and cost targets.

Production management is the backbone of successful manufacturing operations. By leveraging modern tools and adopting efficient processes, companies can boost productivity, cut costs, and enhance product quality. As industries evolve, smart production management will be key to sustainable growth and customer satisfaction.

What is Production Management?

Production management refers to the planning, coordination, and control of manufacturing processes. It ensures that goods are produced efficiently, at the right quality, quantity, and cost. At its core, production management aims to convert raw materials into finished products using optimal resources and methods.

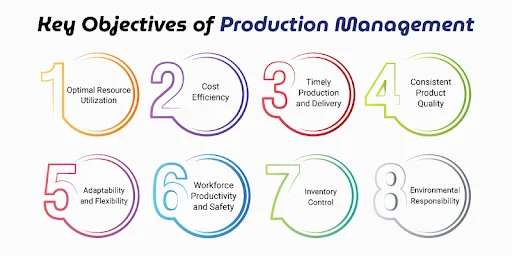

Key Objectives of Production Management

Production management ensures that resources are used efficiently, customer expectations are met, and the organization maintains a competitive edge. Below are the main objectives explained in detail:

1. Optimal Resource Utilization

A primary goal of production management is to use resources like raw materials, labor, equipment, and capital in the most efficient manner. This means minimizing waste, reducing idle time, and ensuring every input contributes to the final product effectively. Efficient resource utilization supports sustainability and increases output.

2. Cost Efficiency

Controlling production costs is essential for maintaining profitability. Production managers work to reduce expenses without compromising product quality. This may include streamlining workflows, automating tasks, and negotiating better material prices. Cost-effective operations allow businesses to offer competitive pricing and improve profit margins.

To make informed financial decisions, it's essential to understand the difference between Manufacturing Cost vs Production Cost, as each impacts budgeting and pricing strategies differently.

3. Timely Production and Delivery

Meeting production schedules is crucial to fulfill customer orders on time. Production management ensures goods are manufactured and delivered within the promised timeframe. Delays can result in lost sales and customer dissatisfaction, while on-time delivery strengthens relationships and enhances brand reputation.

4. Consistent Product Quality

Maintaining a consistent level of product quality is critical. Production managers implement quality control systems and monitor processes to ensure every unit meets the required standards. High product quality reduces the risk of returns or recalls and boosts customer trust and loyalty.

5. Adaptability and Flexibility

In a constantly evolving market, production systems must be adaptable. Whether it's a change in product design, customer demand, or material availability, the production team needs to adjust quickly. Flexibility in production allows companies to stay agile and responsive to external changes.

6. Workforce Productivity and Safety

Maximizing employee productivity while ensuring a safe work environment is another key objective. This involves proper training, fair workload distribution, and adherence to safety protocols. A motivated and protected workforce leads to better performance and reduced risk of workplace accidents.

7. Inventory Control

Managing inventory levels is essential to avoid overstocking or shortages. Production management involves balancing supply with demand using methods like just-in-time inventory, forecasting, and lean practices. Proper inventory control reduces carrying costs and improves cash flow.

8. Environmental Responsibility

Modern production management also aims to reduce environmental impact. This includes using sustainable materials, minimizing waste, and lowering energy consumption. Environmentally responsible production meets regulatory standards and appeals to eco-conscious consumers.

Core Functions of Production Management

Core functions of production management are essential for transforming inputs into high-quality finished goods efficiently and cost-effectively. These functions form the backbone of any successful manufacturing operation and ensure that production goals align with business objectives.

1. Planning

Planning is the first and most critical step in the production management process. It involves forecasting customer demand and determining what products need to be manufactured and in what quantities. This step requires analyzing past sales data, market trends, and seasonal fluctuations to estimate future demand accurately.

Once demand is forecasted, the planning phase defines the necessary resources, including raw materials, machinery, workforce, and production time. It also sets objectives for production efficiency, cost targets, and quality standards. Effective planning ensures that the production system is aligned with business goals and customer expectations, avoiding underproduction or overproduction.

2. Routing

Routing refers to deciding the most efficient path that materials and components must follow during the production process. It outlines the exact sequence of operations required to transform raw materials into finished goods.

This includes selecting the machines, workstations, departments, and even specific workers involved in each step. Routing helps in reducing bottlenecks, minimizing production time, and ensuring optimal use of resources. A well-structured routing process also supports consistent product quality and smooth workflow across departments.

3. Scheduling

Scheduling establishes when each operation or task in the production process should start and finish. It ensures that production activities are timed properly to meet delivery deadlines while maximizing the use of labor and equipment.

There are several types of scheduling, including master production scheduling (MPS), operations scheduling, and detailed task scheduling. A good schedule helps avoid idle time, prevents work overload, and improves order fulfillment. By balancing workload across resources and shifts, scheduling enhances overall efficiency and productivity.

4. Dispatching

Dispatching is the execution phase of production planning. It involves issuing specific orders and instructions to the workforce and machinery to begin production activities. This step ensures that the right tasks are started at the right time and by the right people.

Dispatching includes assigning tasks, providing job cards, issuing raw materials, and instructing operators about job priorities. It plays a key role in converting plans into action and maintaining a steady flow of production work on the shop floor.

5. Monitoring and Control

Once production is underway, continuous monitoring and control are essential to ensure that everything is proceeding as planned. This involves tracking the progress of production tasks, comparing actual performance against the schedule, and identifying any deviations or issues.

Control measures are implemented to correct delays, manage resource shortages, or fix quality issues. Monitoring also involves generating reports and metrics on efficiency, output, and downtime. Effective control helps in maintaining product quality, meeting deadlines, and reducing costs by avoiding waste or rework.

Essential Tools in Production Management

To achieve streamlined operations and high-quality outcomes, modern production management relies on a range of specialized tools. These tools support everything from planning and tracking to quality control and waste reduction. Below is a detailed overview of some of the most impactful tools used in the industry today:.

Enterprise Resource Planning (ERP) Systems

ERP systems serve as the backbone of integrated business operations. In production management, they unify various functions such as procurement, inventory control, production scheduling, and finance into one cohesive system. This integration allows decision-makers to access real-time data, optimize resource use, forecast demand accurately, and manage budgets effectively. ERP systems enhance coordination across departments and improve responsiveness to market changes.

Manufacturing Execution Systems (MES)

MES software plays a critical role on the factory floor. It tracks the entire manufacturing process in real time from the arrival of raw materials to the completion of finished products. MES captures detailed information about machine performance, operator productivity, and work-in-progress, helping managers detect bottlenecks, ensure quality standards are met, and respond swiftly to issues. This level of visibility boosts overall efficiency and helps maintain consistent output quality.

Lean Manufacturing Tools

Lean tools aim to eliminate waste and enhance process efficiency. Techniques such as 5S (Sort, Set in Order, Shine, Standardize, Sustain) improve workplace organization and reduce downtime. Kaizen focuses on continuous, incremental improvements involving employees at all levels. Value Stream Mapping helps visualize and analyze every step of the production process to identify inefficiencies. These tools create a culture of ongoing improvement and cost-effectiveness.

Gantt Charts and Kanban Boards

These visual planning tools are essential for organizing and monitoring production workflows. Gantt charts provide a timeline view of tasks, milestones, and dependencies, making it easier to manage schedules and resources. Kanban boards, on the other hand, offer a more flexible, real-time look at work-in-progress by using columns and cards to represent tasks and their status. Both tools improve transparency and facilitate better communication among teams.

Quality Management Systems (QMS)

QMS ensures that production processes consistently meet customer and regulatory requirements. These systems standardize quality control procedures, document inspections, and manage non-conformances. By tracking performance metrics and facilitating root-cause analysis, QMS helps companies maintain high product quality and comply with industry standards. This not only protects brand reputation but also reduces the risk of costly recalls and rework.

Common Production Management Processes

In production management, selecting the right manufacturing strategy is crucial to meeting customer expectations, optimizing inventory, and controlling costs. The following are some of the most commonly used production processes that companies implement based on their product type, market demand, and operational capabilities:

Make-to-Stock (MTS)

Make-to-Stock is a traditional production strategy where goods are manufactured based on forecasted demand. Companies use historical sales data, market trends, and predictive analytics to estimate future customer needs and produce products in advance. This method allows for quick delivery and higher customer satisfaction for fast-moving items, but it also carries the risk of overproduction or stockouts if forecasts are inaccurate. It is best suited for standardized products with consistent demand.

Make-to-Order (MTO)

In a Make-to-Order process, manufacturing does not begin until a specific customer order is received. This approach allows for greater customization, reduces inventory holding costs, and eliminates the risk of unsold goods. However, it typically results in longer lead times since each product is built from scratch after the order is placed. MTO is ideal for high-value or customized products where customer specifications vary significantly.

Assemble-to-Order (ATO)

Assemble-to-Order combines the benefits of both MTS and MTO strategies. Basic components or subassemblies are produced in advance and kept in inventory, while the final assembly is completed only after an order is received. This hybrid model offers flexibility, faster delivery times compared to MTO, and reduced inventory risk compared to MTS. It is particularly effective for products that come in many variations but share common parts, such as consumer electronics or configurable machinery.

Just-In-Time (JIT)

Just-In-Time is a lean manufacturing strategy focused on minimizing inventory levels by producing goods only when there is actual demand. Components and materials arrive exactly when needed in the production process, which helps reduce storage costs, waste, and overproduction. JIT requires precise coordination with suppliers and a highly efficient production system. While it improves operational efficiency, it can be sensitive to disruptions in the supply chain, making risk management essential.

What Are the 5 M’s of Production Management?

The 5 M’s—Men, Machines, Methods, Materials, and Money—represent the fundamental pillars of production management. While "men" traditionally refers to labor, a more inclusive term is "people," highlighting the human workforce that operates machinery and oversees production. Each element plays a vital role in the manufacturing process. People bring skills and coordination, machines provide the power to produce, methods determine the processes followed, materials are the physical inputs, and money fuels the operation. A production manager’s role involves balancing and optimizing these five elements to ensure efficient, cost-effective, and high-quality output.

What Does a Production Manager Do?

Production management offers strong career prospects and high earning potential. In the U.S., the median annual salary is approximately $116,970, with top professionals earning over $190,000.

The responsibilities of a production manager can vary depending on the industry and specific organization, but their core role remains focused on ensuring smooth and efficient production. Key duties typically include:

- Overseeing the entire manufacturing process, ensuring that resources are used effectively to meet production targets

- Planning and maintaining production schedules and budgets to align with business goals

- Monitoring operations and workflows to identify areas for improvement and boost productivity

- Communicating clearly and consistently with team members, suppliers, stakeholders, and clients to coordinate activities

- Upholding safety standards and product quality to ensure compliance and customer satisfaction

- Managing and supporting the production team, including delegating tasks and resolving personnel issues

- Troubleshooting production challenges, from supply chain delays to equipment malfunctions, and implementing timely solutions

In essence, a production manager serves as the bridge between planning and execution, ensuring that products are manufactured efficiently, safely, and to specification.

Ensuring consistent product performance starts with evaluating your vendor ecosystem — and that’s where understanding how Supplier Quality Engineers improve product reliability becomes essential.

Importance of Production Management in 2025 and Beyond

As global markets evolve and supply chains face increased complexity, production management has become more vital than ever. In 2025 and beyond, businesses are navigating rapid technological change, shifting consumer expectations, geopolitical uncertainties, and sustainability mandates. Effective production management is key to staying competitive in this landscape.

One of the primary reasons production management is essential is its role in ensuring operational efficiency. With rising material and labor costs, businesses must optimize every stage of production to reduce waste and maximize output. Production management enables organizations to allocate resources smartly, reduce bottlenecks, and align production with actual demand, leading to lower costs and higher profit margins.

In today’s customer-centric world, timely delivery and product quality are non-negotiable. Production management ensures that manufacturing processes are reliable, repeatable, and capable of meeting quality standards. This is especially critical as consumers expect faster lead times, more customization, and seamless post-purchase experiences.

Moreover, as digital transformation accelerates, production management must integrate with technologies like IoT, AI, and data analytics. These tools provide real-time insights into machine performance, inventory levels, and workflow efficiency. By leveraging these technologies, businesses can make proactive decisions, predict disruptions, and enhance productivity across the board.

Sustainability is another major driver of change in production management. Stakeholders now expect companies to minimize environmental impact. Through responsible sourcing, energy-efficient processes, and circular production models, modern production management contributes directly to achieving ESG goals.

In 2025 and beyond, companies that invest in smart, agile, and sustainable production management practices will not only survive but thrive. They will be better equipped to respond to market shifts, regulatory changes, and consumer demands—gaining a strategic edge in an increasingly competitive world.

SIXM: Your Partner in Smart Production Management

Production management is the backbone of successful manufacturing operations. By leveraging modern tools and adopting efficient processes, companies can boost productivity, cut costs, and enhance product quality. As industries evolve, smart production management will be key to sustainable growth and customer satisfaction.

At Sixm, we are committed to helping businesses optimize their production strategies with cutting-edge solutions and expert guidance. Whether you’re looking to streamline operations, enhance your Supplier Management Services, or implement the latest industry best practices, our team is here to support your journey toward manufacturing excellence. Stay ahead of the competition by partnering with SIXM—where innovation meets efficiency.