Mexico, China, and other production hubs like Bangladesh, Vietnam, and Turkey all require unique quality control strategies due to differences in regulations, lead times, labeling laws, and compliance frameworks. Mexico’s proximity and USMCA-driven traceability shift timelines, labeling, and documentation. China still offers the deepest testing and supplier networks, while Bangladesh/Vietnam/Turkey bring their own compliance frameworks and risks.

This guide explains how garment QC differs across these markets and helps you design a region-specific inspection approach.

Garment Quality Control Comparison: Mexico vs. China vs. Other Key Markets

Explore how garment quality control standards, timelines, and compliance requirements differ across Mexico, China, and other leading apparel manufacturing markets.

| Factor | Mexico | China | Bangladesh / Vietnam / Turkey |

|---|---|---|---|

| Trade & Traceability | USMCA “yarn-forward” rules demand upstream material documentation. | Mature supplier ecosystem; deep expertise in destination-based QC. | Bangladesh follows RSC/Accord; Vietnam/Turkey focus on EU/US compliance. |

| Labeling Rules | NOM-004-SE-2021 (Spanish labels, fiber %, size, care, country, responsible party). | GB standards for domestic sales; exports follow buyer-market labeling. | Domestic rules vary; exports follow US/EU requirements. |

| Lead Times | 1–7 days to the U.S. via truck/rail; faster rework cycles. | 2–4 weeks by sea; QC must be front-loaded. | Similar to China; Turkey faster into EU; Bangladesh longer queues. |

| Inspection Method | AQL/ISO 2859-1 standard; Normal II severity. | Same, but stronger lab support. | Same standard; Bangladesh has added safety audits. |

| Strengths | Speed, USMCA benefits, and easier onsite follow-ups. | Specialized processes, comprehensive testing, and large capacity. | Bangladesh: large cut-and-sew scale; Turkey/Vietnam: EU/US compliance expertise. |

| Watch-Outs | NOM labeling, USMCA origin docs. | GB labeling compliance, port congestion. | Factory safety remediation timelines, capacity swings, energy volatility. |

Key Factors That Influence Garment Quality Control Across Global Markets

1. Regulatory Requirements Shape QC

Mexico

- USMCA Compliance: To qualify for duty-free benefits, you need traceable documentation from yarn to garment.

- NOM-004-SE-2021 Labeling: Requires Spanish labels showing fiber content, size, care instructions, country of origin, and the responsible party.

China

- GB Standards: For domestic sales, safety compliance (GB 18401) and consumer labeling (GB/T 5296.4) are mandatory.

- Export QC: Labeling and testing align with the buyer’s destination market (US/EU).

Bangladesh, Vietnam, Turkey

- Bangladesh: Follows RSC/International Accord safety audits, impacting inspection timelines.

- Vietnam and Turkey: Focus heavily on EU/US labeling and chemical compliance.

2. Lead Times Impact QC Planning

- Mexico → U.S.: Nearshoring enables delivery in 1–7 days. This allows flexible QC scheduling, more DUPROs, and rapid corrective action.

- China → U.S.: Sea freight takes 2–4+ weeks, so pre-production approvals and inline inspections must occur earlier.

- Bangladesh/Vietnam/Turkey: Similar to China but with regional variations; Turkey offers quicker EU replenishment.

3. Inspection Standards Stay Global, But Execution Differs

Across all regions, ISO 2859-1 / ANSI AQL remains the global benchmark:

- Severity Level: Normal II by default.

- AQL Recommendations: Critical: 0.0 | Major: 2.5 | Minor: 4.0

Mexico: Focuses more on NOM labeling audits.

China: Leverages stronger labs for advanced testing.

Bangladesh: Integrates factory safety compliance into QC cycles.

4. Region-Specific QC Playbooks

Mexico

- Verify USMCA-origin materials early.

- Approve NOM-compliant labels before production.

- Use DUPROs around 20–30% completion.

- Pre-shipment inspections at 80–100% packed.

China

- Conduct early lab tests (colorfastness, azo dyes, formaldehyde).

- Run detailed inline checkpoints.

- Final inspections focus on labeling accuracy and destination-market compliance.

Bangladesh / Vietnam / Turkey

- Bangladesh: Integrate RSC safety verification into audits.

- Vietnam: Monitor capacity utilization and WIP control during peak seasons.

- Turkey: Focus on chemical compliance and fast-turn EU shipments.

5. Universal QC Checklist

- Materials: GSM, color consistency, trims, fastness tests.

- Workmanship: Stitch density, seam strength, bartacks, button pull tests.

- Performance: Wash tests, shrinkage control, appearance after laundering.

- Labeling: Verify country-specific requirements (FTC, NOM, GB).

- Packaging: Barcode checks, carton drop tests, assortment accuracy.

Common QC Pitfalls by Region and How to Avoid Them

Regional differences in regulations, timelines, and compliance frameworks can lead to recurring challenges. Here is an overview of common QC pitfalls by region and the best ways to prevent them.

1. Mexico: Speed vs. Accuracy

Pitfall: Mexico’s proximity to the U.S. enables rapid deliveries, but the fast turnaround often causes teams to skip early fabric tests and hand-feel validations, leading to potential quality inconsistencies.

Fix:

- Approve fabric and trim test results before bulk cutting.

- Schedule a pilot-wash test early to verify shrinkage, colorfastness, and care label claims.

- Integrate NOM-004 label compliance checks during pre-production to avoid last-minute rework.

2. China: Labeling Challenges for Mixed Markets

Pitfall: Factories serving multiple destinations (US/EU/CN) often mix up labeling requirements, resulting in compliance issues or delayed shipments.

Fix:

- Freeze label artwork early based on each destination’s regulations.

- Conduct carton-level audits during pre-shipment inspections (PSI).

- For China domestic sales, ensure labels and testing meet GB standards.

- Partner with third-party QC labs like Intertek or SGS for advanced testing when needed.

3. Bangladesh: Balancing Safety and Timelines

Pitfall: Post-Rana Plaza reforms introduced stricter safety audits through the RMG Sustainability Council (RSC) and the International Accord. However, factory remediation timelines sometimes clash with production schedules, risking shipment delays.

Fix:

- Link purchase order releases to verified RSC safety statuses.

- Set pre-agreed Corrective Action Plan (CAP) milestones with factories.

- Schedule independent mid-build inspections to track compliance without halting production.

Documentation You Can’t Skip

Proper documentation ensures compliance, smooth customs clearance, and full production traceability.

Mexico:

- USMCA origin certificates

- Mill invoices

- Cut tickets

- Pilot-wash photos

- NOM label proofs

China:

- Lab test reports

- PSI records

- Label artwork approvals for each market

Bangladesh:

- RSC audit reports

- CAP tracking logs

- Factory safety certificates

All Regions:

- Master QC checklists

- DUPRO/PSI reports

- Re-inspection pictures

- Final shipment QC sign-off

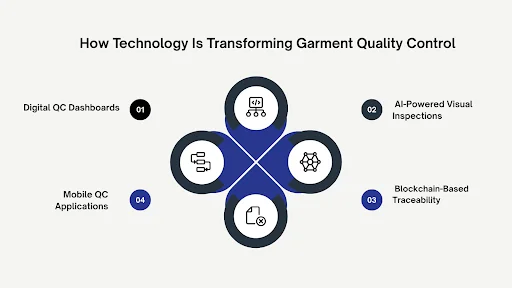

How Technology Is Transforming Garment Quality Control

Global garment quality control (QC) is no longer just about manual inspections and traditional reporting. Brands and manufacturers are increasingly integrating technology-driven solutions into their QC processes. These tools enhance accuracy, speed, and transparency across the entire supply chain. Here is how technology is transforming garment QC:

1. Digital QC Dashboards

Digital QC dashboards centralize all quality data into a single platform, allowing brands, manufacturers, and inspectors to access live information in real time.

Key Features:

- Centralized Defect Tracking: Inspectors can log every defect with images, videos, and descriptions during inline or pre-shipment inspections.

- Real-Time Reporting: Brands receive live updates on QC status, reducing delays caused by manual reports.

- Data Visualization: Dashboards provide trend analysis for recurring issues like stitching defects or fabric inconsistencies.

Why It Matters: For nearshoring in Mexico, where delivery timelines are tight, centralized dashboards help teams spot and address quality concerns before garments leave the factory, minimizing costly rework and returns.

Example: A U.S.-based activewear brand uses a digital dashboard to monitor three Mexican suppliers. When inspectors flag shrinkage issues during DUPRO, the factory adjusts washing temperatures on the same day, saving an entire production batch.

2. AI-Powered Visual Inspections

AI-powered QC systems use machine vision to automatically identify defects in fabric, stitching, and finishing. High-resolution cameras capture images during production, and AI algorithms analyze them against predefined quality benchmarks.

Key Capabilities:

- Automated Defect Detection: Identifies issues like skipped stitches, puckering, color mismatches, and misaligned patterns faster than human inspectors.

- Consistency & Accuracy: AI eliminates human subjectivity, ensuring uniform quality standards across factories.

- Scalability: Supports large-scale production environments, especially in China and Bangladesh, where factories handle thousands of SKUs daily.

Why It Matters: In regions like China, where multi-market production is common, AI systems ensure products meet diverse QC standards simultaneously without relying solely on manual checks.

Example: A denim factory in Guangzhou implemented AI-powered visual inspection and reduced manual inspection time by 45%, cutting defects per shipment by 30%.

To learn how AI and automation are transforming manufacturing and optimizing production workflows, read our detailed article on How AI and Automation Are Reshaping Production Management.

3. Blockchain-Based Traceability

Blockchain creates a secure, tamper-proof digital record of every step in the garment supply chain, from yarn spinning to finished product delivery.

Key Applications:

- USMCA Compliance: In Mexico, where yarn-forward rules require proof of origin, blockchain links raw material certificates, mill invoices, and cutting tickets to specific purchase orders.

- Sustainability Verification: Records certifications like OEKO-TEX or GOTS directly on the blockchain, making audits faster and more reliable.

- Consumer Transparency: Brands can provide QR codes on care labels, allowing shoppers to trace the journey of their garments.

Why It Matters: For brands managing multi-region production (Mexico, China, Bangladesh), blockchain creates a single source of truth for compliance documentation and sustainability reporting.

Example: An American retailer sourcing from Mexico uses blockchain to digitally store USMCA origin certificates. During a customs audit, required documents are accessed instantly, preventing shipment delays and duty penalties.

4. Mobile QC Applications

Mobile QC apps replace manual spreadsheets and paper-based reports with real-time digital inspection tools accessible on smartphones or tablets.

Key Benefits:

- Instant Data Logging: Inspectors upload photos, notes, and defect data directly into centralized systems.

- Live Syncing: Updates are shared immediately with stakeholders in different regions, reducing reporting delays.

- Geotagged Inspections: Enables location tracking of inspections for better transparency and accountability.

Why It Matters: In Bangladesh and Vietnam, where production capacity is often spread across multiple factories, mobile apps allow QC teams to standardize reporting formats and provide instant visibility to overseas buyers.

Example: A European apparel brand working with five factories in Dhaka switched to mobile QC apps. Reporting time dropped from 48 hours to less than 4 hours, speeding up approvals and shipment clearances.

Unified QC systems allow buyers, manufacturers, and third-party inspection agencies to collaborate seamlessly in real time, ensuring faster decisions and consistent quality across the supply chain.

For a deeper understanding of sourcing strategies and choosing the right production destination, explore our complete guide on China vs India vs Mexico: 2025 Sourcing Guide.

SIXM: Your Partner for Unmatched Quality

Effective garment quality control requires strategies tailored to each region to ensure compliance, maintain consistency, and meet delivery timelines. Mexico demands strict USMCA-driven traceability, China provides advanced testing capabilities, and Bangladesh emphasizes factory safety audits, making it crucial to align QC practices with the specific needs of each market.

At SIXM, we help brands streamline QC processes with region-specific strategies, technology-driven solutions, and complete compliance support. As experienced Mexico Manufacturing Consultants, we specialize in guiding brands through complex regulatory frameworks while ensuring seamless production quality. Across Mexico, Asia, and multiple supplier regions, SIXM guarantees consistent product quality.

Partner with SIXM to take your garment quality control to the next level.