The automotive industry is one of the world’s largest revenue-generating sectors and a key contributor to the global economy.

Procurement in the automotive industry directly impacts the efficiency, cost-effectiveness, and competitiveness of manufacturers. Procurement professionals must continuously evolve their strategies to meet the challenges and opportunities of an increasingly complex automotive sector.

In this article, we will explore the evolving role of procurement in the automotive industry. We will examine key strategies, challenges, and trends that are reshaping the way manufacturers source, produce, and deliver their products.

What is Procurement in the Automotive Industry?

Procurement in the automotive industry involves sourcing raw materials, parts, components, and services necessary for vehicle production. It spans from purchasing basic materials like steel and plastic to advanced components like engines and electronic systems. The goal is to ensure a steady supply of quality materials at the best prices.

What Are the Key Procurement Benchmarks in the Automotive Industry?

APQC’s Open Standards Benchmarking® (OSB) in Procurement provides key performance indicator (KPI) benchmarks for organizations in the automotive industry. These benchmarks offer valuable data to assess procurement efficiency, cost-effectiveness, and overall process performance.

The key metric categories covered include:

- Cost Effectiveness

- Cycle Time

- Process Efficiency

- Staff Productivity

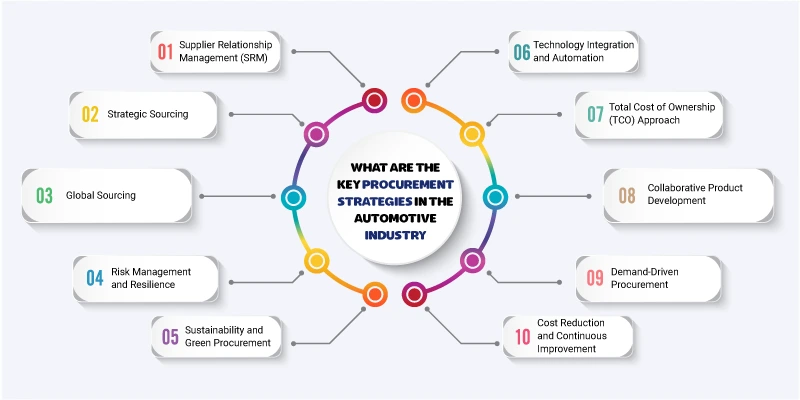

What Are the Key Procurement Strategies in the Automotive Industry?

Automotive companies are continually refining their procurement strategies to stay competitive and meet the evolving demands of the market. Here are some key procurement strategies used in the industry:

1. Supplier Relationship Management (SRM)

Building strong, long-term relationships with suppliers is crucial in the automotive industry. SRM helps foster collaboration, trust, and communication between manufacturers and suppliers, leading to better quality, reliability, and cost efficiency. Automotive companies are increasingly working closely with key suppliers to jointly develop innovative solutions and improve processes.

2. Strategic Sourcing

Strategic sourcing involves evaluating and selecting suppliers based on their long-term value rather than just price. By considering factors like quality, reliability, sustainability, and innovation, automotive companies can secure suppliers who align with their strategic goals. This approach helps reduce supply chain risks, improve product quality, and create competitive advantages.

3. Global Sourcing

To optimize costs and reduce dependency on local suppliers, many automotive companies use global sourcing. This strategy allows manufacturers to tap into a broader pool of suppliers and benefit from lower costs or specialized components not available locally. However, managing a global supply chain requires careful coordination and risk management to mitigate supply disruptions and ensure quality.

4. Risk Management and Resilience

Given the volatility of the global supply chain, automotive procurement teams focus on risk management strategies to anticipate disruptions. This includes diversifying suppliers, monitoring geopolitical factors, and having contingency plans in place for emergencies. A resilient supply chain ensures that companies can respond quickly to changes and maintain production without major delays.

5. Sustainability and Green Procurement

Sustainability has become a key focus in the automotive industry. Companies are prioritizing green procurement strategies by sourcing eco-friendly materials, working with suppliers who follow sustainable practices, and reducing their carbon footprint. This helps meet regulatory requirements, improve brand reputation, and respond to consumer demand for environmentally responsible products.

6. Technology Integration and Automation

Leveraging technology and automation is increasingly central to procurement strategies in the automotive industry. Digital tools, artificial intelligence (AI), and machine learning can streamline procurement processes, reduce errors, and improve decision-making. For example, predictive analytics can be used to forecast demand, automate inventory management, and optimize supply chain operations.

7. Total Cost of Ownership (TCO) Approach

Rather than focusing solely on the purchase price, automotive procurement teams are adopting a Total Cost of Ownership (TCO) approach. This strategy considers all costs associated with a part or material throughout its lifecycle, including maintenance, energy consumption, and disposal costs. By evaluating the full cost, companies can make more informed purchasing decisions and enhance long-term profitability.

8. Collaborative Product Development

Involving suppliers early in the product development process is an effective strategy for reducing costs and improving innovation. Collaborative product development allows manufacturers to tap into supplier expertise, streamline the design process, and reduce time-to-market. This is especially important for complex components like electric vehicle batteries, where supplier collaboration can lead to technological advancements.

9. Demand-Driven Procurement

Automotive companies are moving towards demand-driven procurement models to align purchasing with actual demand. This strategy helps reduce excess inventory, optimize working capital, and respond more effectively to changes in market conditions. Just-in-time (JIT) inventory management is an example of this strategy, where parts and materials are delivered exactly when needed for production.

10. Cost Reduction and Continuous Improvement

Continuous improvement is an essential strategy in the automotive industry, where cost control and operational efficiency are key to maintaining profitability. Procurement teams focus on identifying areas for cost reduction through better supplier negotiations, process improvements, and more efficient use of resources. Lean manufacturing principles are often applied to eliminate waste and optimize procurement operations.

How Can Procurement Help Overcome Challenges in the Automotive Industry?

The automotive industry faces challenges like supply chain disruptions, rising production costs, the shift to electric vehicles (EVs), sustainability demands, labor shortages, and evolving regulations. Procurement plays a key role in helping companies navigate these issues and stay competitive.

Mitigating Supply Chain Risks

One of the biggest challenges facing the automotive industry is supply chain disruptions, which have been exacerbated by global events such as the COVID-19 pandemic and geopolitical tensions. Procurement can help mitigate these risks by diversifying supplier networks, reducing reliance on a single source, and fostering relationships with multiple suppliers across various regions. By ensuring more reliable and stable sourcing, procurement can safeguard against delays and shortages, minimizing disruptions in production.

Managing Rising Production Costs

With increasing prices for raw materials, energy, and labor, automotive manufacturers are under pressure to maintain profitability. Procurement plays a key role in managing these rising costs through strategic sourcing, effective contract negotiations, and supplier management. By identifying cost-effective alternatives, consolidating orders, or leveraging long-term contracts, procurement professionals can help companies keep production costs in check while maintaining quality.

Supporting Technological Transition to Electric Vehicles (EVs)

As the automotive industry shifts toward electric vehicles, procurement can assist by sourcing the necessary components such as batteries, motors, and electronic systems. By working closely with innovative suppliers, procurement can ensure automakers have access to cutting-edge technology at competitive prices. This supports a smooth transition to EV production, helping automotive companies stay ahead of the curve in an increasingly electric-driven market.

Driving Sustainability Initiatives

Consumers and regulators are placing growing pressure on automakers to embrace sustainability. Procurement can support sustainability efforts by sourcing eco-friendly materials, such as recycled metals and biodegradable plastics, and collaborating with suppliers who prioritize environmentally friendly practices. By sourcing sustainable components and incorporating them into the supply chain, procurement helps automotive companies meet their sustainability goals and respond to consumer demand for greener vehicles.

Addressing Labor Shortages and Skills Gaps

The automotive industry is facing labor shortages, especially in specialized areas like electric vehicle production and automation. Procurement can partner with human resources (HR) departments to ensure the right talent is acquired and trained. By securing skilled labor and collaborating on training programs, procurement helps close the skills gap, ensuring that the workforce is equipped to handle new technological demands.

Ensuring Regulatory Compliance

The automotive industry is subject to stringent regulatory standards, which are continually evolving, particularly in areas like environmental impact and safety. Procurement teams must stay informed about these regulatory changes and work closely with legal and compliance teams to ensure that the materials and components sourced meet all necessary standards. This proactive approach reduces the risk of legal issues, fines, and production delays, keeping the company compliant with industry regulations.

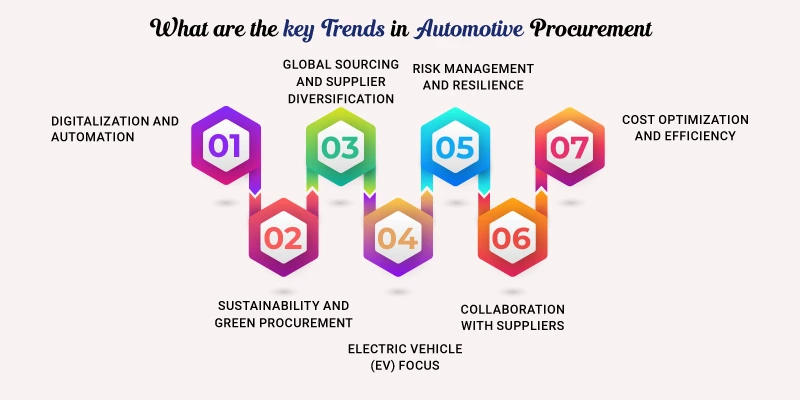

What are the key Trends in Automotive Procurement?

The automotive industry is evolving rapidly, and procurement plays a critical role in shaping the future of vehicle production. Here are the key trends in automotive procurement:

1. Digitalization and Automation

The adoption of digital tools, automation, and artificial intelligence (AI) is streamlining procurement processes, improving efficiency, and enabling real-time tracking of materials and supplier performance.

2. Sustainability and Green Procurement

As consumer demand for eco-friendly products rises, procurement teams are focusing on sourcing sustainable materials and working with suppliers who prioritize environmental responsibility.

3. Global Sourcing and Supplier Diversification

Companies are expanding their supplier networks globally to mitigate risks, reduce costs, and ensure a more flexible supply chain. Diversification helps minimize the impact of regional disruptions.

Must-see: Factors To Consider When Procuring Goods Or Services Globally.

4. Electric Vehicle (EV) Focus

With the growing shift towards electric vehicles, procurement is centered around sourcing new, specialized components such as batteries, electric drivetrains, and advanced electronics for EV production.

5. Risk Management and Resilience

Procurement teams are increasingly focused on building resilience into the supply chain, anticipating disruptions, and developing strategies to quickly adapt to changes in demand or supply.

6. Collaboration with Suppliers

Stronger collaboration and strategic partnerships with suppliers are becoming more common. This approach helps foster innovation, improve product quality, and reduce costs across the supply chain.

7. Cost Optimization and Efficiency

Automakers continue to focus on cost control by negotiating better terms, leveraging economies of scale, and finding new ways to optimize purchasing and inventory management.

These trends highlight how procurement is adapting to changing market demands and technological advancements, positioning itself as a strategic function in the automotive industry.

Drive Innovation in Automotive Procurement with SIXM

At SIXM, we understand the complexities and evolving demands of the automotive industry. As a trusted partner, we specialize in providing innovative procurement solutions that empower automotive companies to navigate supply chain challenges, improve efficiency, and enhance sustainability. Our expertise in supplier management, and strategic sourcing enables us to deliver tailored solutions that align with your business objectives. With SIXM you can stay ahead of industry trends to ensure long-term success in a competitive market. Let's shape the future of automotive procurement together.