Manufacturers and tech firms are managing through one of the most unstable global supply chain climates in recent history. Raw material shortages, volatile trade policies, extreme climate events, and rising operational costs are revealing critical vulnerabilities in global supply networks. At the same time, the rapid adoption of AI, automation, and real-time analytics is reshaping how supply chains are managed.

This blog explores the top challenges facing supply chains in 2025 and how forward-thinking manufacturers and tech firms can build resilience, embrace innovation, and turn disruption into a competitive advantage.

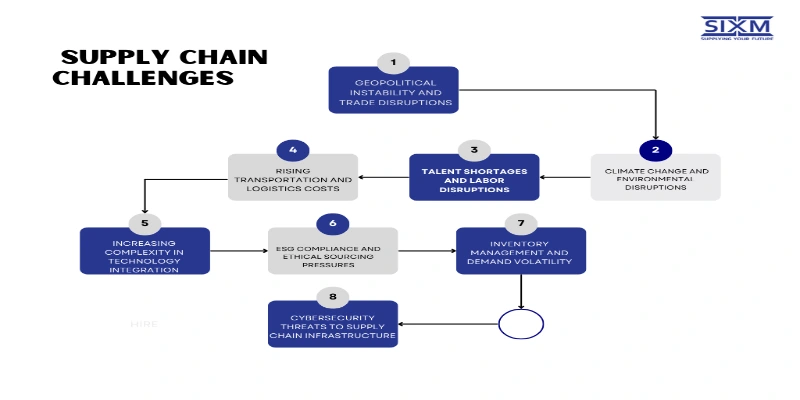

What’s Causing the Supply Chain Challenges in 2025?

Let’s explore the major factors contributing to supply chain disruptions in 2025 and how they’re impacting business operations across industries.

1. Geopolitical Instability and Trade Disruptions

The global trade environment is increasingly volatile. Ongoing conflicts, shifting alliances, and unpredictable policy changes are directly impacting cross-border trade. In 2025, sanctions, export restrictions, and regional tensions continue to disrupt traditional supply routes and force businesses to reassess sourcing strategies.

Key Risks:

- Increased tariffs or trade barriers

- Political unrest in manufacturing hubs

- Supply disruptions from sanctions or border controls

Strategic Response:

Businesses should adopt a multi-country sourcing strategy (such as "China + 1") to reduce overdependence on any one region. Building relationships with alternative suppliers and staying informed about global political developments is essential.

2. Climate Change and Environmental Disruptions

Climate related events such as wildfires, floods, and extreme heat are having a growing impact on transportation, warehousing, and production. In 2025, environmental risks are no longer future concerns. They are present day operational threats.

Examples:

- Flooding of coastal ports

- Droughts disrupting agricultural supply chains

- Extreme weather delaying shipments and production

Strategic Response:

Invest in climate risk mapping, diversify logistics networks, and partner with suppliers that have sustainable and adaptive practices. Resilient supply chains are those that can respond to both sudden shocks and long-term shifts.

3. Talent Shortages and Labor Disruptions

Labor shortages continue to affect key parts of the supply chain, including truck drivers, warehouse workers, skilled technicians, and supply planners. In 2025, talent retention and workforce development remain top concerns, particularly in markets experiencing demographic shifts and rising wage pressures.

Impact Areas:

- Delayed order fulfillment

- Inconsistent production schedules

- Rising labor costs

Strategic Response:

Adopt automation and AI tools where possible to reduce dependency on manual labor. Upskill existing employees and build flexible labor models that can respond to seasonal or regional needs.

4. Rising Transportation and Logistics Costs

Global freight rates may have stabilized compared to the peak-pandemic era, but transportation costs remain elevated. Fuel prices, carrier shortages, and inefficient last-mile delivery models are all contributing to rising logistics expenses in 2025.

Challenges Include:

- Limited container availability

- Driver shortages

- Inefficient warehouse locations

Strategic Response:

Optimize distribution routes using data-driven logistics planning, invest in regional warehousing, and negotiate long-term contracts with reliable carriers to lock in pricing and capacity.

5. Increasing Complexity in Technology Integration

As businesses digitize their supply chains, integrating new tools and platforms can create challenges of their own. Many companies face difficulty aligning ERP systems, supplier portals, inventory tracking, and customer-facing platforms into one cohesive system.

Common Issues:

- Poor data accuracy

- Lack of real-time visibility

- Integration delays between systems

Strategic Response:

Focus on supply chain visibility and interoperability. Choose scalable technologies with robust API support, and ensure all stakeholders from suppliers to fulfillment teams are aligned through shared digital systems.

6. ESG Compliance and Ethical Sourcing Pressures

Environmental, Social, and Governance (ESG) standards are no longer optional. In 2025, businesses face growing pressure from regulators, investors, and consumers to ensure ethical sourcing, fair labor practices, and reduced environmental impact.

Compliance Challenges:

- Traceability across complex supplier networks

- Auditing third-party practices

- Transparent carbon reporting

Strategic Response:

Implement supply chain transparency tools and conduct regular supplier audits. Choose partners with certifications such as ISO 14001 or SA8000 and build ESG criteria into procurement decisions.

7. Inventory Management and Demand Volatility

Customer behavior continues to shift rapidly, with fluctuations in demand causing either inventory shortages or excess. In 2025, real-time demand sensing and accurate forecasting are crucial to balancing stock levels and minimizing costs.

Risks Include:

- Overstocking and markdown losses

- Out-of-stock issues damaging customer loyalty

- High holding costs and waste

Strategic Response:

Use AI-powered demand forecasting and dynamic inventory models that adjust based on sales patterns, seasonality, and macroeconomic signals.

8. Cybersecurity Threats to Supply Chain Infrastructure

Supply chains are increasingly vulnerable to cyberattacks, especially as systems become more interconnected. In 2025, ransomware, data breaches, and system shutdowns pose real threats to operations and reputation.

Vulnerable Areas:

- Third-party software platforms

- Connected IoT devices

- Supplier communication systems

Strategic Response:

Strengthen cybersecurity protocols, conduct regular audits, and establish rapid response plans. Vet third-party vendors for compliance and use secure, encrypted data platforms across your supply network.

To respond effectively to these challenges, businesses need greater visibility, agility, and data-driven decision-making. Learn more in our guide on the Essential Elements of Supply Chain Intelligence.

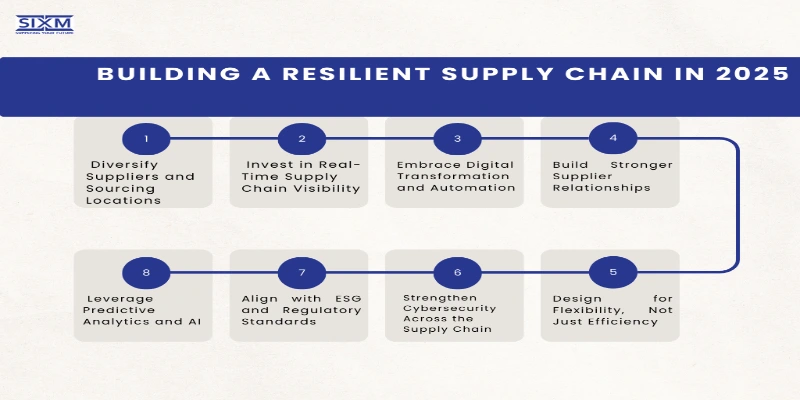

How to Stay Ahead: Building a Resilient Supply Chain in 2025

Building a resilient supply chain requires more than just having backup suppliers or stocking extra inventory. It involves rethinking systems, relationships, technologies, and processes from the ground up. Here are the key strategies to help future-proof your supply chain in 2025:

1. Diversify Suppliers and Sourcing Locations

Relying too heavily on a single supplier or geographic region can create significant risk. Unexpected events like trade conflicts, extreme weather, or political shifts can disrupt the flow of goods. In 2025, businesses are shifting toward multi-country sourcing strategies, allowing them to reduce vulnerability and respond faster when things go wrong. Having multiple supplier options also increases flexibility and negotiation power.

2. Invest in Real-Time Supply Chain Visibility

Without visibility, managing supply chain risks becomes nearly impossible. Businesses need access to real-time information across their entire network, including inventory levels, production timelines, and shipping updates. Investing in platforms that offer end to end visibility helps you identify potential disruptions early, improve coordination, and make better decisions faster.

3. Embrace Digital Transformation and Automation

Technology plays a vital role in making supply chains more resilient. Tools like AI-powered forecasting, warehouse robotics, and automated procurement systems streamline operations and reduce the chance of human error. Automation also makes it easier to scale up or down depending on market conditions, without adding extra strain on your workforce.

4. Build Stronger Supplier Relationships

Trust and communication are critical in any supply chain. Businesses that maintain strong, collaborative relationships with their suppliers are more likely to receive priority support during times of disruption. This includes sharing forecasts, aligning on goals, and regularly reviewing performance together. A well-informed supplier becomes a reliable partner, not just a vendor.

5. Design for Flexibility, Not Just Efficiency

While efficiency has always been a supply chain goal, too much focus on lean operations can leave businesses exposed. Flexible supply chains are better equipped to handle unexpected demand shifts, delivery delays, or sourcing issues. This could mean maintaining safety stock for key products, using more than one shipping method, or having backup production partners ready to go.

6. Align with ESG and Regulatory Standards

Customers, investors, and regulators are paying close attention to how companies manage environmental and social responsibilities. A resilient supply chain is also a responsible one. That means sourcing ethically, monitoring supplier practices, and ensuring compliance with global standards. Companies that fail to prioritize sustainability risk losing both trust and business.

7. Strengthen Cybersecurity Across the Supply Chain

Digital systems make supply chains faster and more connected but also more vulnerable. Cyber threats like data breaches or ransomware attacks can disrupt operations and expose sensitive information. It’s important to have cybersecurity policies in place, regularly assess vendor systems, and train employees on data protection. Keeping your digital infrastructure secure is essential for supply chain continuity.

8. Leverage Predictive Analytics and AI

Being able to anticipate problems before they happen is one of the biggest advantages in supply chain management. Predictive analytics and artificial intelligence help identify trends, forecast demand more accurately, and model different risk scenarios. This kind of foresight allows businesses to act early, stay ahead of disruptions, and maintain stability even in uncertain conditions.

Supply chain resilience in 2025 is not just about reacting to problems , it’s about being ready for them. Businesses that invest in visibility, digital tools, strong partnerships, and flexible systems will be in a better position to grow, adapt, and lead in a constantly changing world.

Maintaining consistent product quality starts with supplier oversight. Discover how Supplier Quality Engineers play a critical role in improving product reliability throughout the supply chain.

Conclusion: Turning Challenges Into Competitive Advantages

While 2025 presents a complex supply chain landscape, it also offers opportunities for innovation and leadership. Businesses that embrace flexibility, invest in technology, and prioritize transparency will not only survive disruptions, they will use them as catalysts for long-term growth.

To strengthen your supply chain strategy this year, begin with a clear understanding of the challenges and build a smarter, more resilient plan. A good starting point is ensuring you're working with the right sourcing supplier in Mexico to enhance quality, cost-efficiency, and supply continuity.