Product sourcing is the process of finding, evaluating, and purchasing products from suppliers or manufacturers to sell or use in your business. It involves identifying the right suppliers, negotiating prices and terms, ensuring product quality, and arranging for production or delivery.

In simple terms, it’s how businesses get the goods they sell.

In this blog, we’ll break down what product sourcing is, explore the different types of sourcing, walk through the step-by-step process, and highlight key challenges to avoid along the way.

Why Is Product Sourcing Important?

- Profit margins: Source at the right price, and you protect your margins.

- Product quality: Reliable suppliers mean fewer defects, returns, and unhappy customers.

- Speed to market: A well-structured sourcing process shortens lead times.

- Scalability: Reliable sourcing supports business growth and consistent inventory levels.

Poor sourcing decisions can lead to delayed shipments, subpar quality, and cash flow issues — especially for businesses dependent on third-party suppliers.

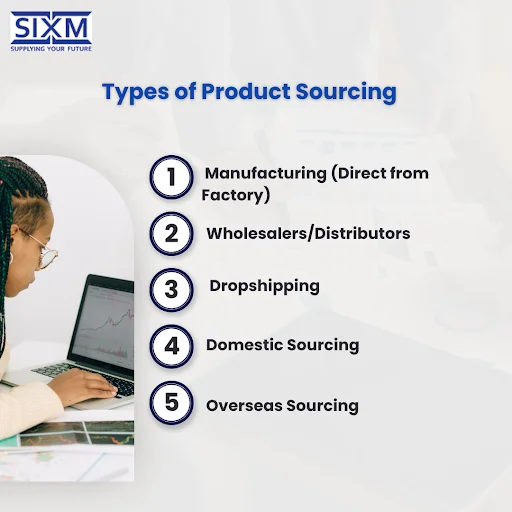

What Are the Different Types of Product Sourcing?

There are several ways businesses can source products, depending on their needs, budget, and operational model:

1. Manufacturing (Direct from Factory)

You work directly with a manufacturer to produce goods, usually under your specifications (custom or private label).

Best for: Large volumes, custom products, brand control

- Pros: Lower cost per unit, full control over product design

- Cons: Higher MOQ (minimum order quantity), more complex logistics

2. Wholesalers/Distributors

Buy bulk goods from wholesalers who get products from manufacturers.

Best for: Quick turnaround, smaller order quantities

- Pros: Easier access, faster lead times

- Cons: Higher prices than factory direct

3. Dropshipping

You partner with a supplier who ships products directly to your customers.

Best for: New eCommerce businesses, low upfront investment

- Pros: No inventory needed, easy to test products

- Cons: Lower profit margins, less control over fulfillment and quality

4. Domestic Sourcing

Sourcing from suppliers within your own country or region.

Best for: Faster shipping, easier communication, ethical manufacturing

- Pros: Lower shipping time, easier QC and returns

- Cons: Typically higher production costs

5. Overseas Sourcing

Purchasing from suppliers in foreign markets (e.g., China, India, Vietnam).

Best for: Cost efficiency at scale

- Pros: Lower unit cost, wider variety of products

- Cons: Longer lead times, higher risk of quality issues, customs complexities

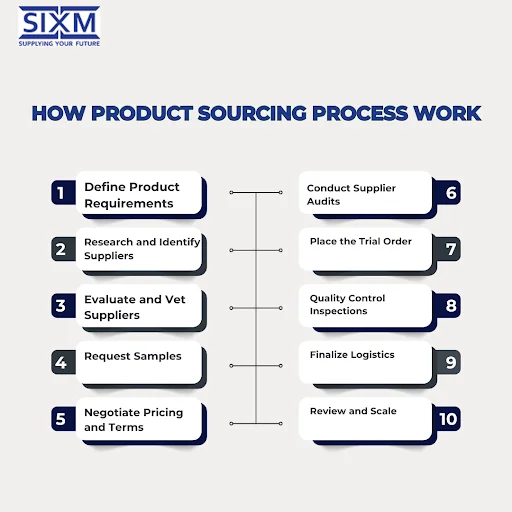

How Does the Product Sourcing Process Work?

A successful sourcing strategy follows a clear and structured process:

- Define Product Requirements

Specifications, materials, certifications, design files, and packaging details. - Research and Identify Suppliers

Use platforms like Alibaba, GlobalSources, IndiaMART, or attend trade shows. - Evaluate and Vet Suppliers

Look at supplier credentials, past clients, factory certifications, and references. - Request Samples

Never place a bulk order without first inspecting a sample. - Negotiate Pricing and Terms

Discuss cost per unit, MOQs, lead time, payment terms, and incoterms (like FOB/CIF). - Conduct Supplier Audits

On-site or remote audits to assess capabilities and compliance. - Place the Trial Order

Start small to test quality, reliability, and communication. - Quality Control Inspections

Hire a third-party quality management company to inspect goods before shipment. - Finalize Logistics

Arrange shipping, customs clearance, and delivery. - Review and Scale

Based on performance, increase order volumes or look for alternative suppliers to reduce risk.

What Are the Main Challenges in Product Sourcing?

Product sourcing isn’t without its challenges. Common issues include:

1. Language and Cultural Barriers

When dealing with overseas suppliers, communication gaps can lead to misunderstandings about specifications, timelines, or pricing. Language differences often result in vague answers or misinterpretations, especially when technical details are involved. In some cultures, saying "yes" may simply mean "I heard you," not that there is agreement or understanding. Without culturally aware communication and clearly documented requirements, small miscommunications can turn into costly mistakes.

2. Unreliable or Fraudulent Suppliers

Not every supplier you find online is legitimate. Some may disappear after taking an advance payment, while others might promise capabilities they do not actually have. Inexperienced buyers are especially vulnerable to scams or misrepresentation. Even among legitimate vendors, reliability varies. Delays, quality issues, or non-compliance with regulations can create serious business disruptions. That is why verifying supplier credentials and conducting third-party audits is essential before entering any agreement.

3. Hidden Costs

While a supplier’s quoted price may look attractive at first, the total landed cost often tells a different story. Duties, tariffs, shipping fees, warehousing, packaging, customs brokerage, and handling charges can quickly add up, especially when sourcing from overseas. Many businesses underestimate these costs, leading to squeezed profit margins or budget overruns. A clear understanding of terms such as FOB, CIF, or EXW and local import laws is critical to avoid surprises.

4. Quality Inconsistency

One of the biggest risks in product sourcing is inconsistent or substandard quality. A supplier might send high-quality samples, but the mass production batch could be different. In the absence of proper quality checks or standardized processes, even minor deviations can affect product performance, customer satisfaction, and brand reputation. Without quality inspections or a quality assurance system in place, issues often go unnoticed until it is too late when goods are already in your warehouse or customers' hands.

5. Supply Chain Disruptions

Geopolitical tensions, port congestion, natural disasters, raw material shortages, or even sudden public health crises can disrupt your sourcing plans overnight. Overreliance on a single supplier or region increases vulnerability to these disruptions. Diversification, strong contingency planning, and real-time supply chain visibility are essential in today’s unpredictable business environment.

This is why many businesses work with quality management companies or sourcing agents to reduce risk and improve efficiency.

Who Can Source Products?

Product sourcing is not limited to large corporations or experienced importers. Almost anyone can source products, as long as they follow the right steps and understand the risks involved. Here’s a breakdown of who can source products and how:

1. Entrepreneurs and Startups

Individuals launching their own brands or online stores can source products directly from domestic or overseas suppliers. Many eCommerce sellers on platforms like Shopify, Amazon, or Etsy start small by sourcing from wholesale markets or using dropshipping models.

2. Small and Medium Enterprises (SMEs)

SMEs often source in bulk to get better margins, especially if they operate physical retail locations or manage their own distribution channels.

3. Large Corporations

Larger businesses with established supply chains often engage in strategic sourcing, which includes evaluating multiple global suppliers, long-term contracts, and supplier diversification to reduce risks.

4. Procurement Professionals

Companies often employ dedicated sourcing or procurement managers to handle vendor selection, price negotiation, compliance, and quality control.

5. Freelancers and Product Sourcing Agents

These are third-party individuals or companies that source products on behalf of others, often for a commission. They are particularly helpful for businesses new to sourcing or operating in foreign markets.

Partner with SIXM for Reliable, Scalable Sourcing Solutions

A structured sourcing process supported by proper vetting, clear communication, and quality checks can make all the difference.

At SIXM, we empower businesses to streamline product sourcing through verified supplier networks, end-to-end quality oversight, and strategic supply chain support. From first contact to final delivery, we help you build sourcing partnerships you can trust. Learn more about our Mexico Sourcing & Procurement Services and how we can help you operate with greater confidence and control.

Get in touch with SIXM today to take control of your sourcing journey with confidence.