Effective supplier data management is no longer a luxury—it's a necessity. Organizations rely on vast networks of suppliers, each generating critical data that impacts procurement, compliance, risk management, and overall supply chain performance. However, managing this data manually or through traditional systems often leads to inefficiencies, inconsistencies, and costly errors.

Artificial Intelligence (AI) is a transformative force reshaping how businesses handle supplier data. By leveraging AI, companies can automate data collection, enhance accuracy, identify risks in real-time, and generate actionable insights. As supply chains grow increasingly complex, the integration of AI into supplier data management isn’t just innovative—it’s essential for achieving operational excellence, agility, and competitive advantage.

At AMREP Mexico, we are committed to embracing advanced technologies like AI to streamline our supply chain operations, ensuring that we deliver the best products and services to our patients. Here's how AI is revolutionizing supplier data management in the healthcare sector.

1. Automating Data Collection and Integration

Managing supplier data involves gathering information from various sources, including spreadsheets, contracts, invoices, and product specifications. Traditionally, this process has been time-consuming, manual, and prone to human error. AI-driven tools can automate data collection, extracting relevant information from different formats and integrating it into a centralized database. This not only reduces the risk of errors but also ensures that data is always up-to-date and easily accessible.

With AI, healthcare organizations can seamlessly integrate data from multiple suppliers, ensuring that all departments have real-time access to critical supplier information, from inventory levels to delivery schedules.

2. Enhancing Data Quality and Accuracy

Inaccurate supplier data can lead to supply chain disruptions, delays in patient care, and financial losses. AI can significantly enhance the quality and accuracy of data by utilizing advanced machine learning algorithms to detect discrepancies, errors, and inconsistencies. AI systems can automatically flag issues such as duplicate entries, outdated contact details, or mismatched order quantities, allowing healthcare professionals to address these issues proactively.

Additionally, AI algorithms can analyze supplier performance over time, identifying patterns that may indicate a risk of future disruptions. This predictive capability allows healthcare organizations to take corrective actions before problems arise, ensuring a smoother and more reliable supply chain.

3. Predictive Analytics for Demand Forecasting

AI-powered predictive analytics can help healthcare organizations forecast supply chain demand more accurately. By analyzing historical data, seasonal trends, and external factors such as population health data or economic conditions, AI can predict which products and services will be needed most in the future. This level of forecasting is essential for managing inventory, ensuring that critical medical supplies are available when needed without overstocking or understocking.

For instance, if a surge in a specific disease or condition is anticipated, AI can help adjust orders to meet the rising demand for relevant supplies, reducing the risk of stockouts and improving patient care.

4. Optimizing Supplier Selection and Evaluation

AI can significantly improve the process of supplier selection and evaluation, helping healthcare organizations identify the best suppliers based on a variety of factors such as price, reliability, quality, and delivery time. By analyzing historical data and performance metrics, AI can assist in choosing suppliers that align with an organization’s specific needs and goals.

Moreover, AI can continuously monitor supplier performance, identifying any potential issues such as delays in delivery or quality problems. This allows healthcare organizations to make data-driven decisions when renewing contracts or selecting new suppliers, ensuring a more resilient and efficient supply chain.

5. Risk Management and Mitigation

In the complex and often unpredictable world of healthcare supply chains, risk management is essential. AI can help identify potential risks within the supply chain by analyzing data for warning signs such as price fluctuations, geopolitical instability, or changes in regulatory requirements. By leveraging AI’s capabilities in real-time monitoring and analysis, organizations can mitigate risks before they impact operations, ensuring that patients continue to receive timely care.

For example, AI can monitor supplier health by analyzing financial stability, news reports, and compliance audits. If a supplier faces a potential disruption—such as a labor strike or regulatory violation—AI can notify relevant stakeholders so they can take immediate action.

6. Improving Supplier Collaboration and Communication

AI-powered platforms can also enhance communication between healthcare organizations and their suppliers. By using natural language processing (NLP) and chatbots, AI can automate routine communication, such as order confirmations, shipment tracking, or invoice processing. This allows procurement teams to focus on more strategic tasks while improving the overall efficiency and responsiveness of supplier interactions.

In addition, AI can help ensure that all stakeholders are aligned, as it can share up-to-date supplier information across departments and locations. This seamless flow of information helps healthcare organizations maintain strong relationships with their suppliers and reduces the risk of miscommunication or delays.

7. Cost Savings and Efficiency

AI's ability to streamline supplier data management results in significant cost savings for healthcare organizations. By automating repetitive tasks, reducing errors, and improving decision-making, AI helps to lower operational costs. Moreover, AI's predictive capabilities can help organizations optimize their inventory, reduce waste, and ensure that resources are used efficiently, further driving down costs.

AI can also help identify opportunities for negotiation with suppliers, allowing organizations to secure better pricing or terms based on supplier performance, demand patterns, or volume discounts. Over time, these savings can be reinvested into improving patient care and expanding healthcare services.

Read More: How To Find A Supplier In Mexico That Will Meet Your Quality Standards

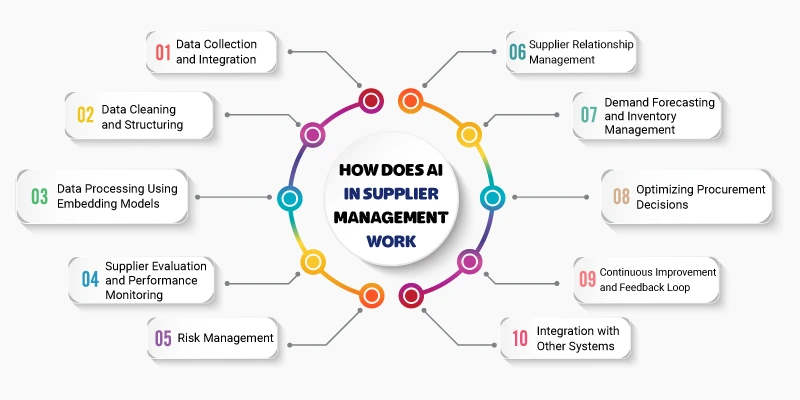

How does AI in supplier management work?

AI in supplier management leverages advanced technologies like machine learning, natural language processing, and automation to streamline processes, enhance decision-making, and improve efficiency. By incorporating AI into supplier management, organizations can optimize their supply chain, reduce risks, and foster better supplier relationships. Here's a breakdown of how AI works in supplier management:

1. Data Collection and Integration

AI begins by gathering vast amounts of data from multiple sources, including:

- Supplier performance data: Metrics like delivery times, product quality, and compliance.

- Financial data: Information about the supplier's financial health, credit scores, and payment history.

- Customer feedback: Insights from customer reviews and satisfaction scores that assess the reliability of suppliers.

- Logistics data: Information related to transportation, shipping times, and warehousing efficiency.

This data is collected from various systems, spreadsheets, emails, contracts, and more.

2. Data Cleaning and Structuring

Once data is collected, AI tools process and clean the data. This step ensures that it's accurate, complete, and properly structured for analysis. Machine learning models often help automate this process, identifying and correcting errors or inconsistencies.

3. Data Processing Using Embedding Models

After the data is cleaned, it's passed through embedding models, which convert unstructured data (like text or documents) into structured formats that AI systems can understand. These models create numerical representations (called vectors) of textual data, allowing the AI to analyze and make sense of information like contracts, emails, and reports.

4. Supplier Evaluation and Performance Monitoring

AI uses the processed data to evaluate suppliers based on several criteria:

- Supplier performance: AI tracks and analyzes historical data, such as delivery consistency, product quality, and regulatory compliance.

- Predictive analytics: Machine learning models predict future supplier behavior by analyzing past performance patterns, helping identify potential risks such as delays or quality issues before they occur.

- Real-time monitoring: AI systems can continuously monitor supplier performance, enabling proactive management of relationships and risks.

5. Risk Management

AI identifies and mitigates potential risks within the supply chain by analyzing both internal and external factors. For instance, it can assess:

- Financial stability: Analyzing financial health to predict whether a supplier might face financial difficulties.

- Geopolitical and market risks: AI models can detect shifts in global markets or regulations that may impact suppliers, such as trade restrictions or rising commodity prices.

AI helps organizations take preemptive actions to avoid disruptions and minimize risk exposure.

6. Supplier Relationship Management (SRM)

AI can improve communication and collaboration between businesses and their suppliers:

- Automated communication: AI tools, like chatbots, can automatically handle routine queries such as order statuses, shipment tracking, and invoice inquiries, freeing up human resources for more strategic tasks.

- Negotiation support: AI analyzes historical contract data and market trends to provide insights and recommendations for better supplier agreements and pricing.

7. Demand Forecasting and Inventory Management

AI enables accurate demand forecasting by analyzing historical data, market trends, and external variables. This helps organizations predict product demand more accurately, ensuring they maintain optimal inventory levels and avoid both stockouts and overstocking.

8. Optimizing Procurement Decisions

AI models help procurement teams make smarter purchasing decisions by:

- Cost optimization: AI identifies cost-saving opportunities, such as negotiating better prices or consolidating purchases across suppliers.

- Smart sourcing: AI tools can recommend the best suppliers based on cost, performance, and reliability, ensuring businesses select partners that align with their goals.

9. Continuous Improvement and Feedback Loop

AI systems continuously learn and improve over time. By incorporating feedback from users about the system's output, AI models can be fine-tuned for better accuracy. This continuous learning process allows AI to adapt to changes in supplier performance, market conditions, and business requirements.

10. Integration with Other Systems

AI integrates seamlessly with other enterprise resource planning (ERP), customer relationship management (CRM), and supply chain management (SCM) systems. This interconnected approach ensures that data flows smoothly between departments, providing a unified view of supplier performance and enabling real-time decision-making.

Challenges in AI-Driven Supplier Data Management

AI holds tremendous potential to transform supplier data management, but it comes with its own set of challenges that organizations must address to realize its full value.

1. Data Quality and Standardization

AI is only as effective as the data it’s given. Inconsistent, incomplete, or siloed supplier data can limit the effectiveness of AI algorithms.

2. Integration with Legacy Systems

Many organizations still rely on outdated procurement or ERP systems, which can complicate seamless integration with modern AI tools.

3. Change Management and Adoption

Introducing AI can face internal resistance. Procurement teams need proper training and change management to embrace new workflows.

4. Data Security and Compliance

Handling sensitive supplier information requires robust data governance frameworks to ensure compliance with global regulations like GDPR.

5. Cost and ROI Clarity

While AI promises long-term gains, upfront costs and unclear ROI timelines can deter investment, especially for mid-sized enterprises.

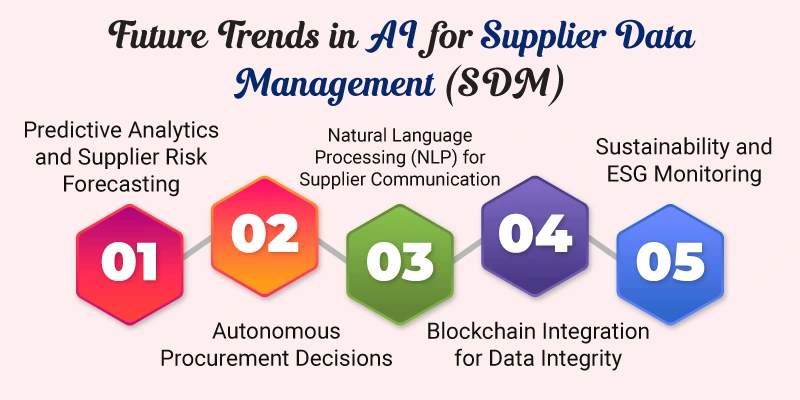

Future Trends in AI for Supplier Data Management (SDM)

As AI technologies continue to evolve, their role in supplier data management is set to grow more intelligent, autonomous, and strategic. Here are some key trends shaping the future of AI in SDM:

1. Predictive Analytics and Supplier Risk Forecasting

Future systems will not only flag risks but also predict them—allowing procurement teams to act before issues arise.

2. Autonomous Procurement Decisions

AI will increasingly recommend or even make low-risk decisions autonomously, speeding up processes and reducing human error.

3. Natural Language Processing (NLP) for Supplier Communication

AI-driven chatbots and NLP tools will streamline communication, automate responses, and extract key information from supplier documents.

4. Blockchain Integration for Data Integrity

Combining AI with blockchain will enable real-time, immutable supplier data sharing, boosting trust and traceability.

5. Sustainability and ESG Monitoring

AI will play a bigger role in tracking and analyzing supplier sustainability metrics and compliance with ESG standards.

AMREP’s Approach: Merging AI with Deep Supply Chain Expertise

AI empowers organizations to operate with greater agility, transparency, and confidence. As technology continues to evolve, those who embrace AI today will be the ones leading the supply chains of tomorrow.

At AMREP, a Top-Rated Procurement Company, we understand that efficient supplier data management is the foundation of a resilient and responsive supply chain. By harnessing the power of AI, we help businesses move beyond manual processes to unlock greater accuracy, transparency, and strategic insight. As the demands of global supply networks continue to grow, AMREP remains committed to driving innovation and empowering organizations to stay ahead. With AI at the core of supplier data transformation, the future of supply chain excellence starts here.