A Supplier Quality Engineer (SQE) plays a critical role in ensuring that a company’s suppliers consistently deliver high-quality materials, components, or products that meet predefined standards. Their responsibilities span technical evaluation, process improvement, compliance assurance, and collaboration with both internal teams and external vendors.

Supplier Quality Engineers act as the bridge between a company’s supply chain and its quality assurance requirements. Their job is not just about catching defects; it is about preventing them from occurring in the first place through proactive planning, assessment, and collaboration with suppliers.

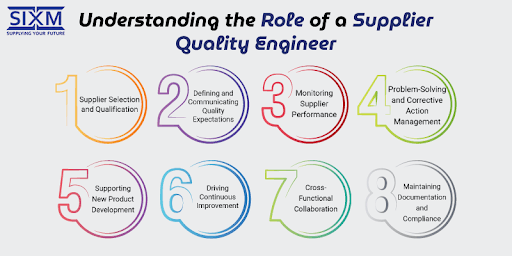

Understanding the Role of a Supplier Quality Engineer

At its core, the SQE role focuses on maintaining and improving the quality of goods and materials received from third-party vendors. But the job is multifaceted, requiring a mix of technical expertise, communication skills, and strategic thinking.

Here’s a breakdown of what a Supplier Quality Engineer does and why their work is essential to successful manufacturing operations.

-

Supplier Selection and Qualification

Before a supplier is approved to deliver parts or materials, an SQE evaluates their capabilities through audits, quality system reviews, and performance assessments. This ensures that only vendors with strong quality management systems, adequate production capacity, and proven reliability are brought into the supply chain.

Key tasks include:

- Conducting supplier audits and on-site assessments

- Reviewing certifications (ISO 9001, IATF 16949, etc.)

- Assessing manufacturing processes and quality controls

- Approving suppliers based on objective criteria

-

Defining and Communicating Quality Expectations

SQEs are responsible for establishing clear quality expectations and standards for suppliers. These expectations are documented in technical specifications, quality agreements, and inspection protocols.

They work closely with internal teams such as engineering, procurement, and quality control to:

- Develop product-specific quality standards

- Define inspection and testing requirements

- Set up supplier scorecards for ongoing evaluation

- Ensure alignment on compliance and regulatory standards

-

Monitoring Supplier Performance

Once a supplier is on board, the SQE continuously monitors their performance. This includes tracking defect rates, delivery accuracy, non-conformities, and responsiveness to issues. Regular reporting helps identify trends and areas for improvement.

Performance monitoring involves:

- Analyzing quality metrics and key performance indicators (KPIs)

- Investigating recurring issues or quality escapes

- Conducting periodic performance reviews with suppliers

-

Problem-Solving and Corrective Action Management

If a supplier delivers non-compliant parts or materials, the SQE takes charge of investigating the root cause and implementing corrective and preventive actions (CAPA). This process ensures that issues are addressed thoroughly and don’t recur.

Responsibilities include:

- Leading root cause analysis (using tools like 5 Whys, Fishbone Diagrams, etc.)

- Collaborating with suppliers to implement effective corrective actions

- Verifying and validating fixes through audits or sample testing

-

Supporting New Product Development

When new products are launched or existing ones are redesigned, SQEs ensure that suppliers are fully prepared to meet the required quality and delivery standards. They play a key role in the New Product Introduction (NPI) process by:

- Conducting First Article Inspections (FAI)

- Overseeing pre-production runs

- Validating supplier tooling and process readiness

- Ensuring smooth ramp-up with minimal quality issues

-

Driving Continuous Improvement

Beyond fixing problems, SQEs are expected to drive continuous improvement in supplier processes and systems. This long-term approach helps reduce waste, improve consistency, and lower costs.

They may:

- Initiate Lean Six Sigma or Kaizen projects with suppliers

- Provide training and guidance on quality best practices

- Recommend process automation or tooling upgrades

- Benchmark performance against industry standards

-

Cross-Functional Collaboration

SQEs work closely with various internal teams, including:

- Procurement to align sourcing decisions with quality goals

- Engineering to ensure technical requirements are met

- Manufacturing to manage production readiness and incoming inspections

- Compliance to meet regulatory or customer-specific standards

This collaboration ensures a unified approach to supplier management and product quality.

-

Maintaining Documentation and Compliance

A major part of the SQE’s responsibilities involves keeping accurate records for traceability, compliance, and future audits. This includes:

- Supplier audit reports

- CAPA documentation

- Control plans and inspection results

- Supplier qualification and re-evaluation records

Proper documentation is especially critical in regulated industries such as automotive, aerospace, medical devices, and electronics.

Why Supplier Quality Engineers Matter

Quality issues at the supplier level can result in costly delays, product recalls, or damage to brand reputation. A skilled Supplier Quality Engineer acts as the first line of defense, ensuring that external vendors align with internal expectations and customer demands.

By focusing on prevention, collaboration, and long-term improvement, SQEs:

- Enhance product reliability

- Improve supplier relationships

- Reduce total cost of quality

- Strengthen supply chain resilience

To truly understand their impact, it's important to look at how Supplier Quality Engineers improve product reliability by ensuring consistency, reducing defects, and driving continuous improvement across the supply base.

What Are the Benefits of Being a Supplier Quality Engineer?

Being a Supplier Quality Engineer (SQE) offers a rewarding career path with a range of personal, professional, and financial benefits. Here are some of the key advantages:

-

High Demand Across Industries

SQEs are essential in sectors like automotive, aerospace, electronics, medical devices, and consumer goods. As companies rely more on global supply chains, the demand for skilled SQEs continues to grow.

-

Competitive Salary and Career Growth

Supplier Quality Engineers typically earn attractive salaries, especially as they gain experience and certifications. The role can also lead to senior quality management, operations, or supply chain leadership positions.

-

Diverse and Dynamic Work Environment

The job involves working with multiple departments including engineering, procurement, and production, as well as suppliers worldwide. This variety keeps the work interesting and offers continuous learning opportunities.

-

Opportunity to Drive Real Impact

SQEs directly influence product quality, customer satisfaction, and operational efficiency. Their efforts help reduce defects, minimize costs, and prevent recalls, making a visible impact on business performance.

-

Strong Foundation in Problem-Solving

The role hones analytical skills through tools like root cause analysis, Six Sigma, and FMEA. This problem-solving expertise is valuable across many engineering and leadership roles.

-

Travel and Global Exposure

Many SQE roles involve site visits, supplier audits, and international collaboration, offering chances to travel and gain global experience.

-

Gateway to Specialized Certifications

SQEs often pursue respected certifications such as:

- Certified Quality Engineer (CQE)

- Six Sigma Green/Black Belt

- ISO Lead Auditor

These credentials enhance job prospects and professional credibility.

-

Job Security and Flexibility

Quality assurance is non-negotiable in most industries, giving SQEs strong job stability. Additionally, the skills are transferable, allowing flexibility across roles and regions.

To grasp the full scope of their strategic value, explore why Supplier Quality Engineering matters in modern manufacturing and how it shapes the foundation for scalable, high-quality production.

Final Thoughts

The role of a Supplier Quality Engineer is more strategic than ever. As businesses strive for faster production, tighter margins, and zero-defect products, SQEs play a key role in aligning suppliers with these expectations. Their ability to balance technical oversight with relationship management makes them essential to modern manufacturing success.

As your company scales its operations or manages a global supply chain, having a strong Supplier Quality Engineering team is essential for shifting from reactive problem-solving to proactive quality assurance. Working closely with Procurement & Sourcing Specialists, SQEs ensure that supplier capabilities align with quality, cost, and delivery targets, helping businesses stay competitive in today’s fast-paced market.

At SIXM, we understand the mission-critical role of supplier quality in sustainable manufacturing. Our approach helps businesses integrate quality engineering principles early in the supply chain lifecycle, reducing risk, improving compliance, and driving long-term value.