Uncertainty is the new normal in today’s business world. From market volatility and cybersecurity threats to supply chain issues and changing regulations, companies are constantly navigating risks that can disrupt operations and damage their reputation. Traditionally, companies relied on historical data and reactive strategies to manage risk. But those days are quickly becoming a thing of the past. Enter predictive analytics—a transformative approach that's reshaping the way organizations identify, evaluate, and proactively manage risk.

What Is Predictive Analytics?

Predictive analytics is the use of statistical techniques, machine learning algorithms, and data mining to analyze historical and current data to make informed predictions about future events. By recognizing patterns and trends, predictive models can forecast the likelihood of specific outcomes, giving organizations a proactive edge.

In the context of supply chain risk management, predictive analytics helps answer questions like:

- What disruptions are likely to occur?

- How will market fluctuations impact our inventory?

- Which suppliers pose the greatest risk?

- How can we respond faster to minimize impact?

Why Traditional Risk Management Falls Short

Traditional supply chain risk management relies heavily on historical data, manual monitoring, and reactive responses. While this approach can work for static or low-risk environments, it quickly falls apart under:

- Complex global supply chains with hundreds of touchpoints

- Volatile market conditions

- Rapidly evolving customer expectations

- Emerging risks like cyber threats, pandemics, and climate change

These challenges demand a shift from reactive to proactive, data-driven risk management—and that’s exactly where predictive analytics delivers.

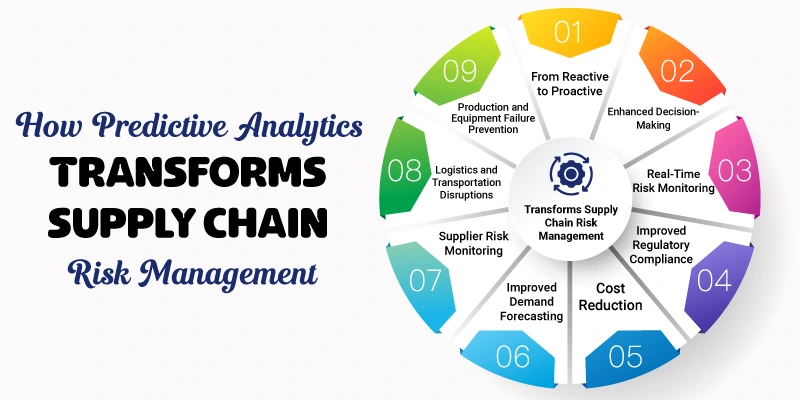

How Predictive Analytics Transforms Supply Chain Risk Management

Predictive analytics is revolutionizing supply chain risk management — enabling smarter decisions, greater agility, and stronger resilience in the face of uncertainty.

1. From Reactive to Proactive

Traditionally, risk management focused on responding to issues after they occurred. Predictive analytics flips this model. By leveraging large datasets from internal and external sources, organizations can detect warning signs early—before they escalate into a full-blown crisis.

For example, a bank can analyze customer transactions and behavioral data to predict the likelihood of loan default, enabling early intervention or adjustments in lending strategies.

2. Enhanced Decision-Making

Predictive models provide data-backed insights that empower decision-makers to evaluate various risk scenarios with greater accuracy. These models can simulate outcomes under different conditions, helping companies choose the best course of action.

In the insurance sector, for instance, predictive analytics can assess policyholder risk profiles to set premiums more accurately and reduce fraud.

3. Real-Time Risk Monitoring

Modern predictive analytics tools can process and analyze data in real time, offering instant alerts and continuous monitoring. This dynamic approach is crucial in sectors like cybersecurity, where threats evolve rapidly, and response times are critical.

By using real-time predictive analytics, companies can identify anomalies—such as unusual network activity or login patterns—that may indicate a breach, and act swiftly to contain the damage.

4. Improved Regulatory Compliance

With regulations constantly evolving, staying compliant is a challenge. Predictive analytics can help organizations anticipate changes in regulatory environments and adapt accordingly. Moreover, it can identify compliance risks by detecting patterns of non-compliance before audits or penalties occur.

Financial institutions, for example, use predictive models to monitor transactions for anti-money laundering (AML) compliance, significantly reducing the risk of regulatory violations.

5. Cost Reduction

By preventing incidents and minimizing their impact, predictive analytics can save companies significant resources. The ability to prioritize risks based on potential impact and probability ensures that organizations focus efforts where they’re needed most—avoiding unnecessary expenses.

6. Improved Demand Forecasting

Poor demand planning leads to overstocking, stockouts, and missed revenue. Predictive analytics uses past sales, seasonality, and external signals (e.g., economic indicators, weather) to accurately forecast demand, reducing inventory risk.

7. Supplier Risk Monitoring

Predictive models evaluate supplier reliability using data on delivery history, financial health, geopolitical risk, and social sentiment. Early warning systems can flag potential failures before they impact operations.

8. Logistics and Transportation Disruptions

Using real-time tracking, traffic data, and historical patterns, predictive analytics optimizes routes and identifies potential transportation delays before they occur.

9. Production and Equipment Failure Prevention

Sensors and IoT devices feed real-time data into predictive models that detect signs of equipment wear or failure, enabling preventive maintenance.

Read More: Embracing Sustainable Sourcing Practices: Your Guide to a Greener Procurement Strategy

Real-World Applications

Predictive analytics is no longer a futuristic concept—it’s already delivering measurable value in supply chains across the globe. Here are some real-world examples of how organizations are applying it to anticipate, manage, and even avoid critical risks:

- Healthcare: Hospitals use predictive analytics to identify high-risk patients, prevent readmissions, and manage resources more efficiently.

- Manufacturing: Predictive maintenance models analyze equipment performance data to foresee failures, reducing downtime and repair costs.

- Retail: Businesses forecast demand and supply chain disruptions to optimize inventory and reduce operational risks.

- Finance: Predictive credit scoring models assess borrower risk more precisely than traditional methods.

Practical Steps: How to Implement Predictive Analytics for Risk Management

1. Define Risk Objectives and KPIs

Start with SMART goals for risk mitigation (e.g., reduce stock outs by 20%, improve supplier risk visibility by 30%).

2. Consolidate and Clean Your Data

Integrate data from multiple sources (ERP, CRM, logistics platforms, sensors). Ensure it’s clean, consistent, and relevant.

3. Select the Right Tools and Platforms

Choose platforms that support real-time analytics, machine learning, and easy visualization—like SAS, Tableau, Azure, or custom Python models.

4. Build the Right Team

Collaborate across departments: IT, supply chain, procurement, and data science. Ensure alignment between business needs and technical capabilities.

5. Start Small, Scale Strategically

Begin with a focused risk area (like supplier performance). Use results to gain buy-in, then expand to broader use cases.

Challenges and How to Overcome Them

Here are some common obstacles and practical strategies to overcome them:

| Challenge | Solution |

|---|---|

| Data silos and inconsistency | Implement centralized data warehouses and master data management. |

| Lack of in-house expertise | Upskill existing staff or partner with analytics consultants. |

| Resistance to change | Use pilot programs to show value early and win stakeholder trust. |

| Cost concerns | Leverage scalable cloud-based solutions and open-source tools. |

The Role of Emerging Technologies

Predictive analytics doesn’t work in a vacuum. It gains power through integration with:

- Artificial Intelligence (AI): Enhances model accuracy and speed.

- IoT & Edge Computing: Enables real-time insights at the source of data.

- Blockchain: Adds traceability and trust to supplier and logistics data.

- Cloud Computing: Supports scalability and accessibility across the enterprise.

These technologies deepen analytics capabilities, allowing companies to move from “predicting risk” to prescribing responses automatically.

Read More: Understanding Procurement in Engineering and Its Importance

The Future: Building a Resilient and Responsive Supply Chain

In an era of frequent disruption, the ability to anticipate and act on risk is not just a competitive edge—it’s a survival imperative. Predictive analytics is enabling supply chains to move from fragile and reactive to resilient and responsive.

Future supply chains will rely on predictive insights to:

- Preempt disruptions before they cascade

- Shift from static planning to dynamic response

- Improve sustainability and ethical sourcing

- Adapt rapidly to changes in demand and supply conditions

Turning Insight into Action: The SIXM Advantage

Risk is inevitable, and predictive analytics empowers organizations to anticipate challenges before they arise, make smarter decisions, and build resilient, future-ready supply chains. By transforming risk management from a reactive function to a strategic advantage, businesses can not only protect their operations but also unlock new levels of efficiency and innovation. At SIXM, we’re committed to helping businesses harness the power of predictive analytics to navigate uncertainty with confidence. At SIXM, we specialize in helping businesses unlock this potential, particularly through our Sourcing & Procurement Engineering Services, which integrate advanced analytics to optimize decision-making and reduce vulnerabilities across the supply chain.

Partner with SIXM to build a smarter, more resilient supply chain—powered by data, driven by results.