Electronics manufacturing is a complex process involving intricate components, high-speed automation, and absolutely no margin for error on the assembly lines. In this high-stakes industry, quality control (QC) is not just a checkpoint; it is a continuous commitment that defines product reliability, builds customer trust, and shapes long-term brand success.

This guide explores how quality control works in electronics manufacturing, why it’s critical, the challenges companies face, and the modern strategies that can improve product quality.

What Is Quality Control in Electronics Manufacturing?

Quality control in electronics manufacturing refers to the processes and systems used to ensure that electronic components and finished products meet defined quality standards, functional requirements, and safety regulations. It includes inspection, testing, documentation, and feedback loops across every stage of the product life cycle, from raw material sourcing to final product packaging.

Why Quality Control Matters in Electronics

Poor quality control can lead to:

- Product failures in the field

- Costly recalls and repairs

- Damage to brand reputation

- Regulatory penalties

- Safety hazards for users

Electronics manufacturers must achieve near-perfect product consistency, particularly in high-demand sectors like aerospace, automotive, healthcare devices, and consumer electronics.

What Are the Key Areas of Quality Control in Electronics Manufacturing?

Quality control in electronics spans multiple stages of the manufacturing process, each with its own set of critical checks to ensure product reliability and performance.

1. Incoming Material Inspection

Before production begins, raw materials and components such as PCBs, ICs, resistors, and capacitors must be inspected to ensure they match specifications.

QC checks include:

- Visual inspection

- Dimensional verification

- X-ray analysis (for internal structures)

- Supplier certifications

2. In-Process Quality Control (IPQC)

This is the heart of QC, where defects are caught during production rather than post-assembly. Inspections happen at different stages of SMT (Surface Mount Technology) or through-hole assembly lines.

IPQC methods include:

- AOI (Automated Optical Inspection)

- SPI (Solder Paste Inspection)

- Functional testing

- Sampling inspection

3. Final Product Testing

Before packaging, each product undergoes final checks to validate performance, durability, and safety.

Common final tests:

- ICT (In-Circuit Test)

- Functional test (FCT)

- Burn-in test (stress testing under load)

- ESD (Electrostatic Discharge) testing

- RF/Signal integrity testing (for devices with connectivity)

4. Environmental and Reliability Testing

To ensure the product survives real-world conditions, specialized tests are conducted in labs.

These include:

- Thermal cycling and shock testing

- Humidity exposure

- Vibration testing

- Salt spray (for corrosion resistance)

What Are the Major Quality Standards in Electronics Manufacturing?

To ensure consistency and compliance, manufacturers often adhere to international quality standards, including:

- ISO 9001 – General quality management

- IPC-A-610 – Acceptability of electronic assemblies

- IPC-A-600 – PCB workmanship standards

- ISO/TS 16949 – Automotive electronics

- ISO 13485 – Medical device manufacturing

- RoHS and REACH – Environmental compliance for hazardous substances

What Are the Common Quality Challenges in Electronics Manufacturing?

Despite advanced systems, manufacturers often face recurring quality issues, such as:

- Soldering Defects

- Cold solder joints

- Bridging

- Insufficient solder

- Tombstoning

- Component Misalignment

Caused by misprogrammed pick-and-place machines or board warping. - PCB Delamination or Warping

Due to high heat exposure or poor material selection. - Electrostatic Discharge (ESD) Damage

Improper grounding or human handling can silently kill components. - Counterfeit Components

Especially in global sourcing, fake or reused parts can compromise quality. - Inadequate Documentation

Without clear work instructions, QA plans, and traceability, maintaining quality is nearly impossible.

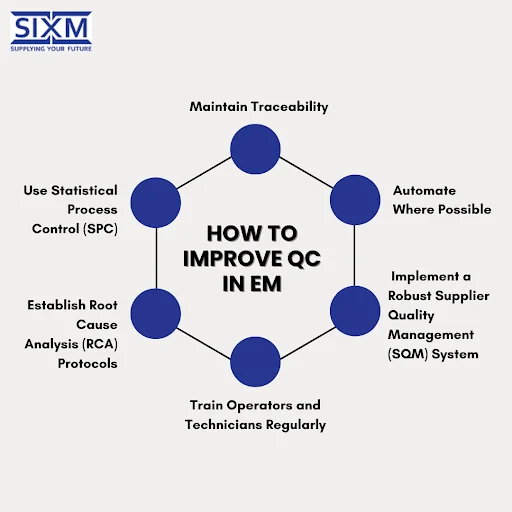

How to Improve Quality Control in Electronics Manufacturing

Improving quality control requires a proactive approach that combines advanced technology, skilled personnel, and standardized processes to prevent defects before they occur. Below are key strategies that can help electronics manufacturers enhance their quality control systems across every stage of production.

1. Automate Where Possible

Use AOI, SPI, and X-ray systems for real-time defect detection. Automation reduces human error and improves inspection accuracy.

2. Implement a Robust Supplier Quality Management (SQM) System

Audit and qualify suppliers. Track incoming defects and enforce corrective actions.

3. Train Operators and Technicians Regularly

Skilled personnel can identify and resolve potential defects early. Use IPC-certified training programs.

4. Establish Root Cause Analysis (RCA) Protocols

Do not just fix defects; identify their root cause using tools like the 5 Whys, Fishbone diagrams, or Failure Mode and Effects Analysis (FMEA).

5. Use Statistical Process Control (SPC)

Collect real-time production data and apply control charts to detect process variations before they create defects.

6. Maintain Traceability

Track every component and process step with serial numbers or barcodes. This simplifies audits, recalls, and warranty claims.

What Is the Role of Quality Control Teams in Electronics Manufacturing?

Effective QC in electronics depends on collaboration among:

- Supplier Quality Engineers (SQEs) – Ensure component quality from external sources

- Process Engineers – Optimize assembly lines to reduce defects

- Quality Inspectors and Technicians – Conduct in-line and final inspections

- Test Engineers – Design and maintain testing protocols

- QA Managers – Oversee compliance and customer satisfaction metrics

Curious about the responsibilities and impact of SQEs? Read our detailed breakdown on What Does a Supplier Quality Engineer Do? to understand how they ensure supplier performance, product quality, and compliance from the ground up.

How Is Digital Transformation Shaping Quality Control in Electronics Manufacturing?

Modern factories are embracing Industry 4.0 technologies to make QC smarter and more predictive:

- IoT Sensors monitor temperature, humidity, and machine performance in real time.

- AI and Machine Learning detect anomalies from image data or production patterns.

- MES (Manufacturing Execution Systems) tracks production and quality data across shifts.

- Digital Twins simulate production environments to test changes before implementation.

Want to dive deeper into the role of quality experts in manufacturing? Check out our guide on How Supplier Quality Engineers Improve Product Reliability to learn how they help reduce defects, ensure compliance, and build stronger supplier relationships.

Strengthen Your Supply Chain with Trusted Quality Control Experts

Quality control in electronics manufacturing isn’t just about catching defects; it is about building robust systems that prevent them. From material inspection to final testing, every step must be optimized, documented, and monitored continuously. In a global, fast-moving, and highly regulated industry, quality is not optional — it is the foundation of trust, innovation, and profitability.

As global manufacturing evolves, making the right decisions today can secure your supply chain for tomorrow. At SIXM, our team of experienced Procurement & Sourcing Specialists works alongside you to ensure quality control, supplier reliability, and operational efficiency. With the right partnership, you gain the agility, insight, and support needed to stay competitive in a shifting landscape.