Supply chains must operate quickly and smoothly. Businesses need real-time insights to stay competitive. This is where data analytics steps in. Data analytics is a necessity. By turning raw data into actionable insights, businesses can improve forecasting, streamline operations, and make smarter decisions in real time. From inventory management to risk mitigation, analytics is reshaping every link in the supply chain.

In this blog, we’ll explore how data analytics is driving greater efficiency, agility, and resilience in supply chain management—and why companies that embrace it are leading the way.

What Is Data Analytics?

Data analytics is the process of collecting, processing, and analyzing data. It helps businesses make informed decisions. In the supply chain, it uncovers patterns, predicts demand, and reduces waste.

At its core, data analytics involves:

- Collecting data from various sources

- Cleaning and organizing the data

- Analyzing the data using tools and techniques

- Interpreting the results to support decisions

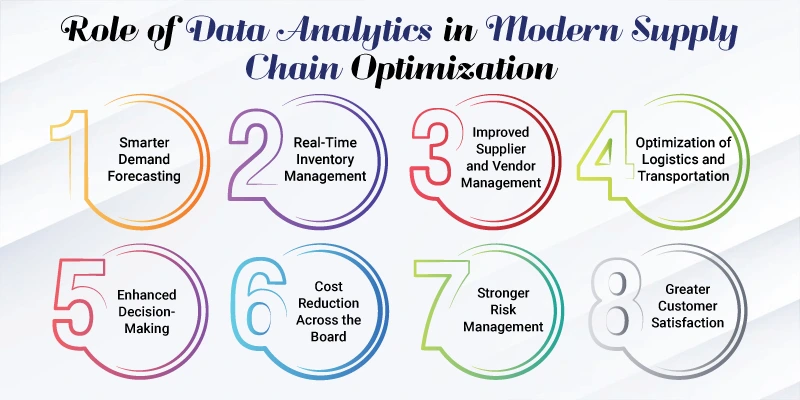

Role of Data Analytics in Modern Supply Chain Optimization

Data analytics is transforming how businesses plan, manage, and improve their supply chains. It turns raw data into actionable insights, helping companies stay competitive and efficient.

Let’s explore the key roles analytics plays in optimizing today’s supply chains.

1. Smarter Demand Forecasting

Predicting customer demand used to rely on guesswork or historical trends alone. Today, data analytics makes forecasting smarter and more accurate.

Companies use advanced algorithms to analyze:

- Historical sales data

- Market trends

- Seasonal fluctuations

- Promotions

- Customer behavior

With this insight, they can forecast demand more precisely. This means fewer stockouts, less overstock, and better production planning. It also helps reduce storage costs and improves customer satisfaction.

2. Real-Time Inventory Management

Knowing what’s in stock at any moment is vital. Traditional inventory checks are slow and error-prone. Data analytics changes that.

With real-time tracking, businesses can:

- Monitor inventory levels across multiple locations

- Detect stock imbalances quickly

- Automate restocking processes

- Reduce holding costs

By analyzing stock movement patterns, companies can fine-tune reorder points and safety stock levels. This leads to a leaner, more responsive inventory system.

3. Improved Supplier and Vendor Management

Suppliers are key players in any supply chain. Their performance directly affects product quality, delivery speed, and overall efficiency. Data analytics helps track and evaluate supplier performance.

Businesses can measure:

- Delivery times

- Defect rates

- Order accuracy

- Pricing trends

With these insights, companies can:

- Identify top-performing suppliers

- Flag potential risks early

- Strengthen supplier relationships

- Negotiate better terms

This leads to fewer delays and more consistent supply chain operations.

4. Optimization of Logistics and Transportation

Transportation is one of the most expensive parts of the supply chain. Data analytics helps reduce those costs through route optimization and load planning.

Using real-time traffic data, weather patterns, fuel costs, and delivery schedules, companies can:

- Find the fastest and most cost-effective routes

- Reduce fuel consumption

- Minimize delays and detentions

- Improve on-time delivery rates

Predictive analytics also helps anticipate disruptions before they happen, allowing rerouting and rescheduling without chaos.

5. Enhanced Decision-Making

Supply chain decisions must be fast and based on facts. Data analytics supports this with clear, real-time dashboards and reports.

Executives and managers can:

- Spot trends instantly

- Identify bottlenecks early

- Simulate different strategies

- Make data-driven decisions

This speed and accuracy help companies respond to market changes and customer needs with agility.

6. Cost Reduction Across the Board

From production to delivery, inefficiencies add up. Data analytics identifies where waste is happening and how to fix it.

It reveals:

- Underused resources

- Unnecessary steps in the process

- High-cost suppliers or carriers

- Frequent causes of errors or rework

By acting on these insights, businesses can streamline operations and cut costs—without sacrificing quality.

7. Stronger Risk Management

Supply chains face many risks: natural disasters, geopolitical tensions, supplier failures, or sudden demand spikes. Data analytics improves risk management by offering predictive insights.

Companies can:

- Model "what-if" scenarios

- Prepare contingency plans

- Monitor global risk factors in real-time

- React quickly when disruptions occur

This reduces downtime, protects revenue, and builds a more resilient supply chain.

8. Greater Customer Satisfaction

Ultimately, data analytics helps companies serve customers better. When the supply chain runs smoothly:

- Products are available when and where customers want them

- Deliveries arrive on time

- Customers can track their orders in real time

With fewer errors and delays, customer trust grows. Happy customers lead to repeat business and positive reviews.

Read More: How Predictive Analytics Can Transform Risk Management

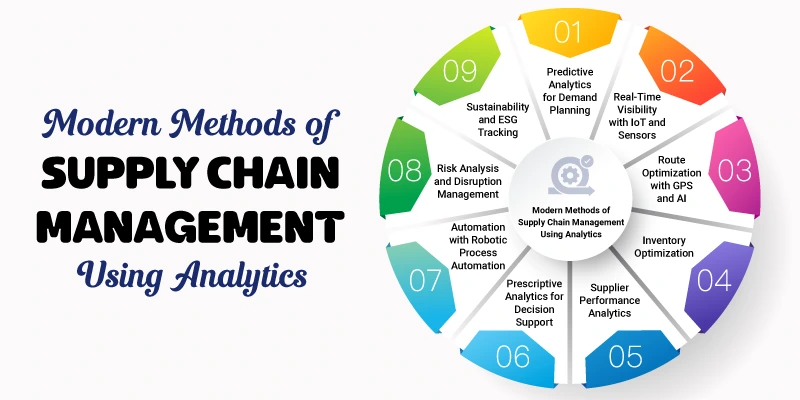

Modern Methods of Supply Chain Management Using Analytics

Supply chain management has changed dramatically in recent years. Businesses now rely on data and advanced analytics to manage their supply chains smarter and faster.

Let’s explore the modern methods that use analytics to improve every part of the supply chain.

1. Predictive Analytics for Demand Planning

Predictive analytics uses historical data, market trends, and machine learning to forecast future demand. This helps companies:

- Avoid stockouts and overstock

- Plan production more accurately

- Adjust to seasonal changes

- Respond to customer trends faster

Tools like time-series analysis and AI-driven models make forecasting more precise than ever.

2. Real-Time Visibility with IoT and Sensors

Modern supply chains use Internet of Things (IoT) devices and sensors to track goods in real-time. These devices collect data on:

- Location of shipments

- Temperature and humidity (for sensitive goods)

- Vehicle performance

- Delivery status

Analytics platforms process this data to provide real-time visibility and alerts, so companies can act fast if something goes wrong.

3. Route Optimization with GPS and AI

Transport and logistics have become smarter with analytics. Advanced software now uses:

- GPS data

- Traffic patterns

- Weather forecasts

- Fuel cost data

This helps plan the most efficient routes, saving time and fuel. AI also adapts routes in real-time based on road conditions or unexpected delays.

4. Inventory Optimization

Analytics helps manage inventory across warehouses, stores, and distribution centers. Key benefits include:

- Lower carrying costs

- Faster turnover

- Balanced stock levels

- Better warehouse space usage

Machine learning can even recommend when to reorder or shift stock based on demand, lead times, and sales velocity.

5. Supplier Performance Analytics

Modern systems track supplier data over time. Companies can evaluate suppliers based on:

- Delivery times

- Product quality

- Cost accuracy

- Responsiveness to changes

This leads to better negotiations, fewer disruptions, and stronger partnerships.

6. Prescriptive Analytics for Decision Support

Prescriptive analytics goes a step further. It not only shows what is happening but also recommends actions. In supply chain management, it can help:

- Choose the best supplier mix

- Allocate inventory across regions

- Plan promotions based on stock levels

- Simulate responses to market changes

It helps decision-makers pick the best options with the highest ROI.

7. Automation with Robotic Process Automation (RPA)

Analytics supports automation in routine supply chain tasks. RPA bots can:

- Process orders

- Update inventory records

- Send shipment notifications

- Match invoices with purchase orders

This reduces human error and speeds up operations.

8. Risk Analysis and Disruption Management

Modern tools analyze risks by monitoring data like:

- Global news

- Weather patterns

- Political events

- Supplier status

Predictive models assess the impact and suggest mitigation strategies. Companies can act early and avoid costly delays.

9. Sustainability and ESG Tracking

Analytics also plays a key role in sustainable supply chains. Companies track emissions, energy use, and ethical sourcing using data. This helps:

- Meet regulatory requirements

- Reduce waste

- Improve brand image

- Build a greener supply chain

Why Some Businesses Are Still Struggling with Supply Chain Data

Many companies are using analytics to improve speed, cut costs, and predict demand. But some businesses still lag behind.

Despite having access to more data than ever, they struggle to use it effectively. Why? The reasons vary, but most fall into a few key categories.

1. Poor Data Quality

Bad data leads to bad decisions. Many businesses collect supply chain data from different sources—suppliers, warehouses, transportation systems, and customer orders. But if that data is:

- Incomplete

- Outdated

- Duplicated

- Inconsistent

…it becomes nearly impossible to trust or analyze. Without clean, accurate data, analytics tools can’t deliver real value.

2. Siloed Systems

In many companies, departments work in silos. The procurement team, warehouse, finance, and logistics often use separate tools. These systems don’t always communicate well. As a result:

- Data is trapped in different platforms

- Teams can’t see the full picture

- Decision-making is delayed or based on limited info

Integrating systems is complex but essential for data-driven supply chain management.

3. Lack of Skilled Talent

Even with good data, many businesses lack the people to manage and interpret it. Data analysts and supply chain experts are in high demand. Smaller companies, in particular, may not have:

- A dedicated data team

- In-house technical skills

- Training for existing staff

This leads to underused tools and missed opportunities for improvement.

4. Outdated Technology

Some companies still rely on spreadsheets or legacy systems. These tools can’t handle:

- Real-time updates

- Large volumes of data

- Advanced analytics or AI

Modern supply chains move fast. Without the right technology, businesses fall behind competitors who can make faster, smarter decisions.

5. Fear of Change

Digital transformation can be overwhelming. Some leaders worry about:

- The cost of new systems

- Training employees

- Disrupting current workflows

Change management is hard—but avoiding change is riskier. Without investment in data and analytics, inefficiencies and blind spots grow over time.

6. Data Security and Privacy Concerns

As data grows, so do concerns about protecting it. Some businesses hesitate to adopt new tools due to fears about:

- Data breaches

- Compliance with laws like GDPR or CCPA

- Sharing sensitive info with partners

While these are valid concerns, strong data governance and modern cloud solutions offer reliable protection.

7. No Clear Strategy

Finally, many businesses collect data without knowing what to do with it. They lack a clear supply chain data strategy. This means:

- No clear goals for data use

- No alignment between teams

- Random or reactive decision-making

To succeed, companies need a plan. They must define what they want to achieve, what data they need, and how to measure progress.

Also Read: Role of AI in Supplier Data Management

Best Practices for Successfully Integrating Data Analytics

Many businesses invest in tools but struggle to get results. To succeed, you need the right strategy, systems, and mindset.

Here are the best practices for successfully integrating data analytics into your business.

1. Start with Clear Goals

Before you gather data or choose tools, define what you want to achieve. Ask questions like:

- What problems are we solving?

- What decisions do we want to improve?

- Which business areas will benefit most?

Clear goals help you focus on the right data, tools, and teams.

2. Build a Strong Data Foundation

Good analytics depend on good data. Make sure your data is:

- Accurate

- Consistent

- Complete

- Timely

Clean up existing data and put processes in place to keep it that way. Use data validation, deduplication, and regular audits.

3. Break Down Silos

In many businesses, data lives in different departments or systems. This limits visibility and slows decision-making.

Integrate your systems and encourage cross-team collaboration. Create a single source of truth by connecting:

- Sales platforms

- Supply chain systems

- Customer databases

Finance and operations tools

Data should flow across the organization, not get stuck in silos.

4. Choose the Right Tools

Don’t just chase trends. Pick tools that match your goals and team’s skill level. Consider:

- Cloud-based platforms for flexibility

- Tools with built-in AI or machine learning

- Dashboards for easy, real-time reporting

- Integration capabilities with existing software

Test tools before fully adopting them. Start small, then scale up.

5. Invest in Skills and Training

Analytics is only powerful when people know how to use it. Train your team to:

- Understand data

- Use analytics tools

- Interpret dashboards and reports

- Apply insights to real-world problems

Hiring skilled analysts or partnering with consultants can also help.

6. Encourage a Data-Driven Culture

Make data part of everyday decisions. Encourage teams to:

- Ask questions using data

- Share insights openly

- Back up ideas with numbers

Leadership must set the tone. When managers lead with data, others will follow.

7. Start Small, Then Scale

You don’t need to overhaul everything at once. Start with one business function or project, such as:

- Improving inventory forecasting

- Reducing delivery delays

- Analyzing customer feedback

Show quick wins, build momentum, then expand analytics into more areas.

8. Monitor, Measure, and Adjust

Track the impact of your analytics efforts. Measure:

- Cost savings

- Time improvements

- Increased accuracy

- Better customer satisfaction

Use this feedback to adjust your strategy, fix issues, and scale success.

9. Prioritize Data Security and Ethics

Protect customer and company data. Make sure your systems follow:

- Data privacy laws (like GDPR, CCPA)

- Access control policies

- Regular security audits

Also, be transparent about how data is used. Ethics should guide your analytics strategy.

The Future of Data Analytics in Supply Chain

The evolution of data analytics in supply chain management is far from over. As new technologies and tools continue to emerge, businesses will find even more innovative ways to optimize their supply chains. Predictive analytics, real-time visibility, AI and machine learning, and blockchain are just the beginning of a more data-driven and efficient future.

For companies willing to embrace these trends, the rewards are significant—improved operational efficiency, better customer satisfaction, and a more resilient and adaptable supply chain. The key is to stay ahead of the curve, continuously innovate, and harness the power of data analytics to drive smarter, more sustainable decisions.

Turning Insights Into Action

Data creates clarity. At SIXM, we turn that clarity into action. Partner with SIXM and discover how data-driven strategies can transform your operations.

For organizations looking to optimize their procurement strategies and streamline operations, partnering with a Top-Rated Procurement Company like SIXM can provide the expertise and tools needed to drive lasting success.

Let data lead the way to smarter, more efficient supply chains.